Applied Mathematics

Editor's pick

Research Article

A simple harmonic quantum oscillator: fractionalization and solution

By Iqbal M. Batiha, Iqbal H. Jebril, Abeer A. Al-Nana, Shameseddin Alshorm

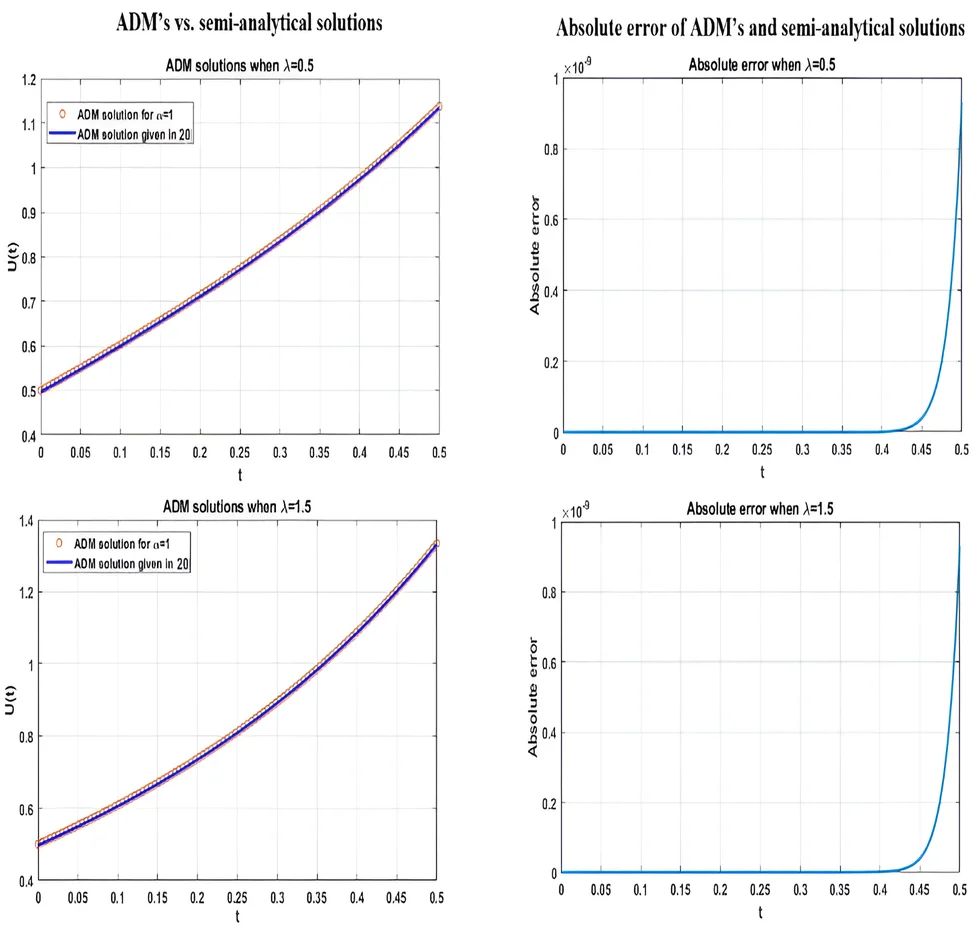

A quantum mechanical system that mimics the behavior of a classical harmonic oscillator in the quantum domain is called a simple harmonic quantum oscillator. The time-independent Schrödinger equation describes the quantum harmonic oscillator, and its eigenstates are quantized energy values that correspond to various energy levels. In this work, we first fractionalize the time-independent Schrödinger equation, and then we solve the generated problem with the use of the Adomian decomposition approach. It has been shown that fractional quantum harmonic oscillators can be handled effectively using the proposed approach, and their behavior can then be better understood. The effectiveness of the method is validated by a number of numerical comparisons.

March 2, 2024

Informatics

Most cited

Research Article

Fault diagnosis and health management of bearings in rotating equipment based on vibration analysis – a review

By Adnan Althubaiti, Faris Elasha, Joao Amaral Teixeira

November 26, 2021

Applied Mathematics

Most cited

Research Article

A convolutional neural network method based on Adam optimizer with power-exponential learning rate for bearing fault diagnosis

By Youming Wang, Zhao Xiao, Gongqing Cao

June 30, 2022

Applied Mathematics

Most cited

Research Article

A review on wind turbines gearbox fault diagnosis methods

By H. Gu, W. Y. Liu, Q. W. Gao, Y. Zhang

January 27, 2021

Applied Mathematics

Most cited

Research Article

Bearing fault diagnosis based on improved VMD and DCNN

By Ran Wang, Lei Xu, Fengkai Liu

August 15, 2020

Applied Mathematics

Mathematical Models in Engineering

Research Article

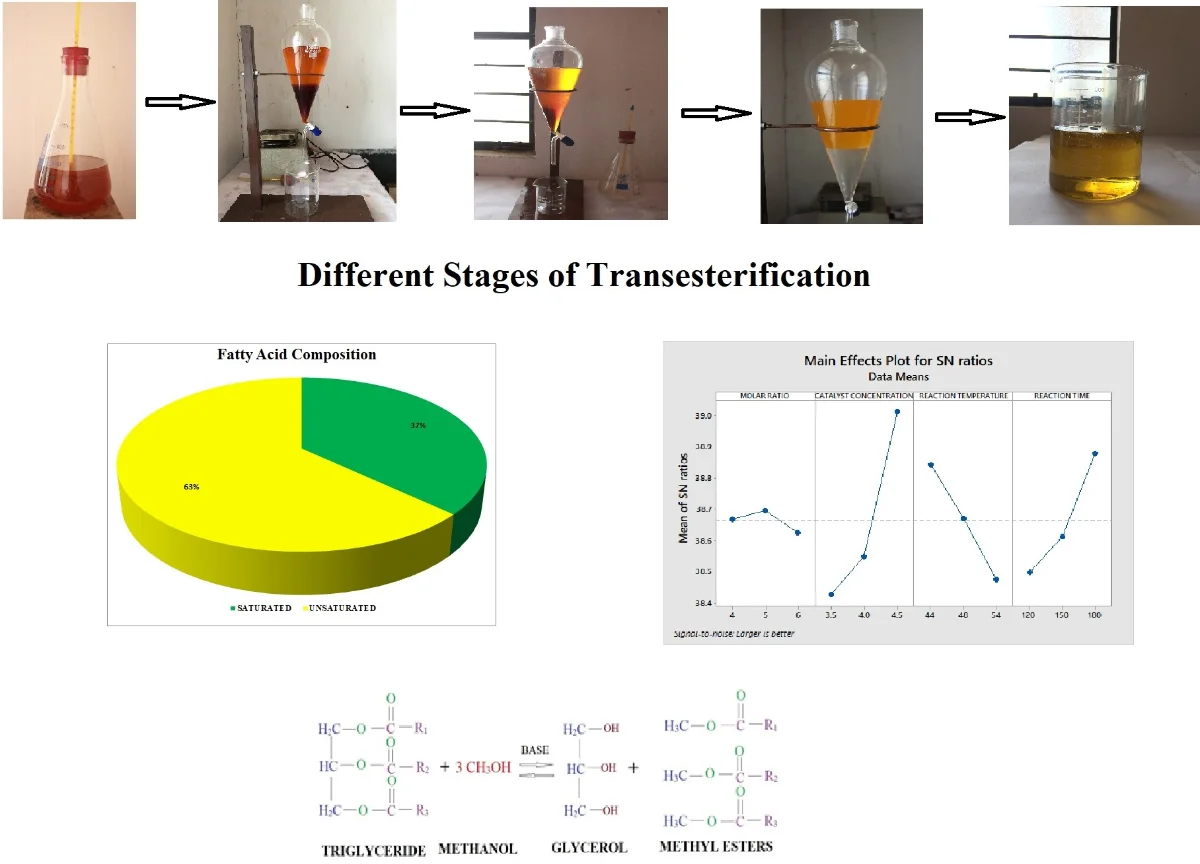

Optimization of palm methyl ester and its effect on fatty acid compositions and cetane number

This paper proposes the Taguchi based optimization technique for the production of biodiesel from palm oil. For this purpose, L9 orthogonal array was successfully used for better yield estimation by using Minitab-18 software. Different process variables like molar ratio, catalyst concentration, reaction time and reaction temperature were studied. A predicted yield of 92.06 % was achieved by regression analysis by maintaining the process variables of molar ratio 5:1 (methanol to oil), 4 grams of catalyst concentration (NaOH), 180 minutes of reaction time and 44°C of reaction temperature. Experimentations were conducted on the same process variables and achieved a yield of 91.65 %. By this it is clear that both experimentation and regression analysis by Taguchi are in good agreement with an error of 0.41 % which may be acclaimed as experimental error. The fatty acid compositions (FAC) were also analyzed and it is found that 37.12 % saturated and 62.88 % unsaturated fatty acids present in the palm methyl ester (PME). By using the FAC of PME the Cetane number was predicted as 55.38. The predicted Cetane number from FAC tally with experimental Cetane number. The PME is characterized for different fuel properties by following the international standards. And it is concluded that catalyst concentration and reaction temperature are the important parameters which influence PME yield, Taguchi based optimization technique will helps in predicting the maximum yield with minimum number of experiments.

March 31, 2019

Informatics

Research Article

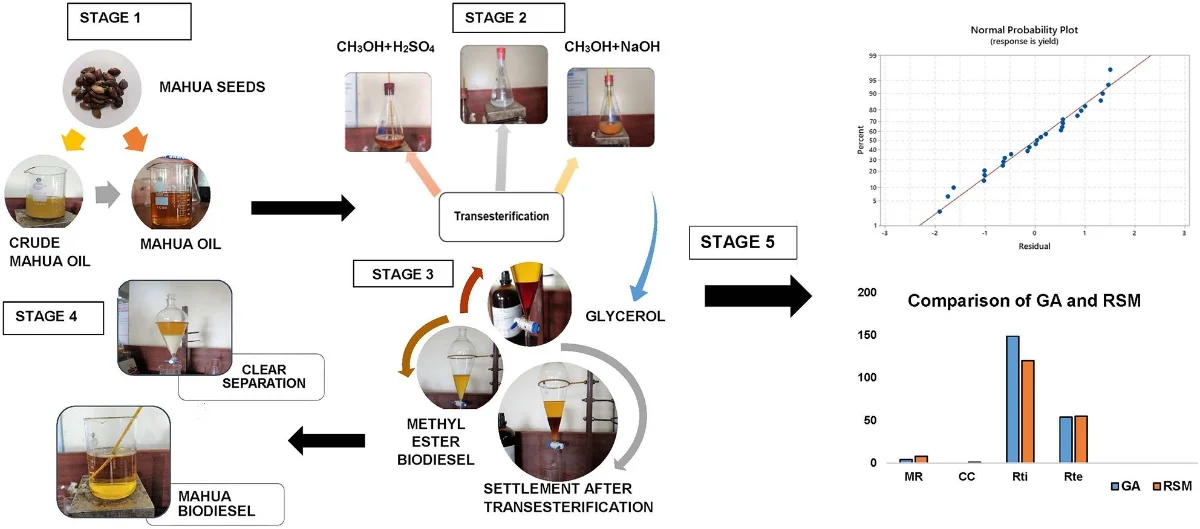

Optimization and modelling of mahua oil biodiesel using RSM and genetic algorithm techniques

In this present investigation, four important process parameters of catalyst concentration, molar ratio, reaction time, and reaction temperature were studied and optimized using Box Behnken assisted response surface method (RSM) and Genetic Algorithm (GA) to achieve the maximum mahua oil biodiesel yield. For this purpose, 27 experiments were conducted randomly based on the design matrix using statistical software MiniTab®2019. A maximum yield of 91.32 % is achieved in RSM, catalyst concentration and reaction time are identified as influence parameters in biodiesel yield. GA modelling show an improvement of 4.96 % in biodiesel yield compared to RSM approach. Both techniques are successfully tested in prediction and modelling the biodiesel yield from mahua oil. The obtained biodiesel from the transesterification process is blended with standard diesel fuel at various proportions (B10 to B90) and tested for different fuel properties. All the biodiesel blends are observed within the limits of international standards of ASTMD-6751 and EN-14214. The results indicate that the chosen models are highly accurate in achieving maximum biodiesel yield and mahua biodiesel is recommended as the best alternative fuel to diesel engines without any major modifications in the engine design.

June 2, 2020

Informatics

Research Article

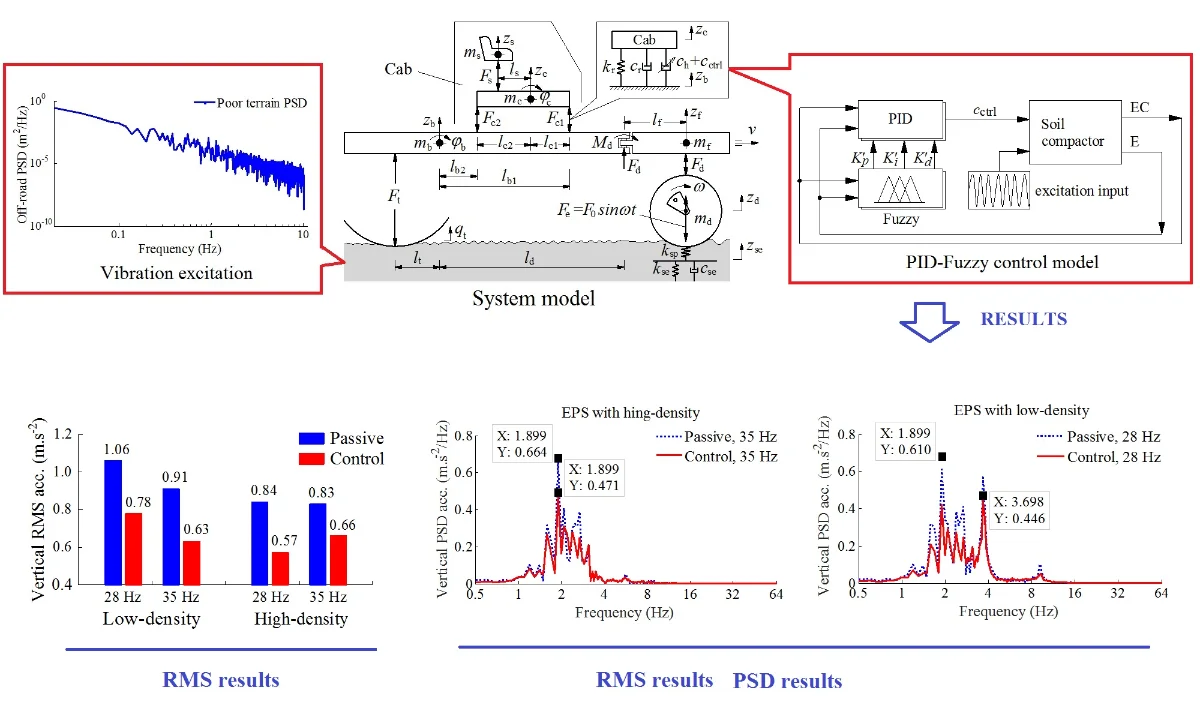

Performance of PID-Fuzzy control for cab isolation mounts of soil compactors

To improve the soil compactor ride comfort, a combined control method of Fuzzy and PID control is proposed to control the cab isolation system of soil compactor based on the non-linear vehicle dynamic model. The vibration excitation sources are concerned by the vibrator drum and elastoplastic soil (EPS) interactions in the compression process. The power-spectral-density (PSD) and weighted root-mean-square (RMS) of acceleration responses of both the vertical driver’s seat and pitching cab angle are chosen as the objective functions. The research results show that both the PSD and weighted RMS values of the vertical driver’s seat and pitching cab angle are significantly reduced by using the PID-Fuzzy control under various EPSs in the low-frequency region, especially on the EPS with high-density.

December 31, 2019

Informatics

Research Article

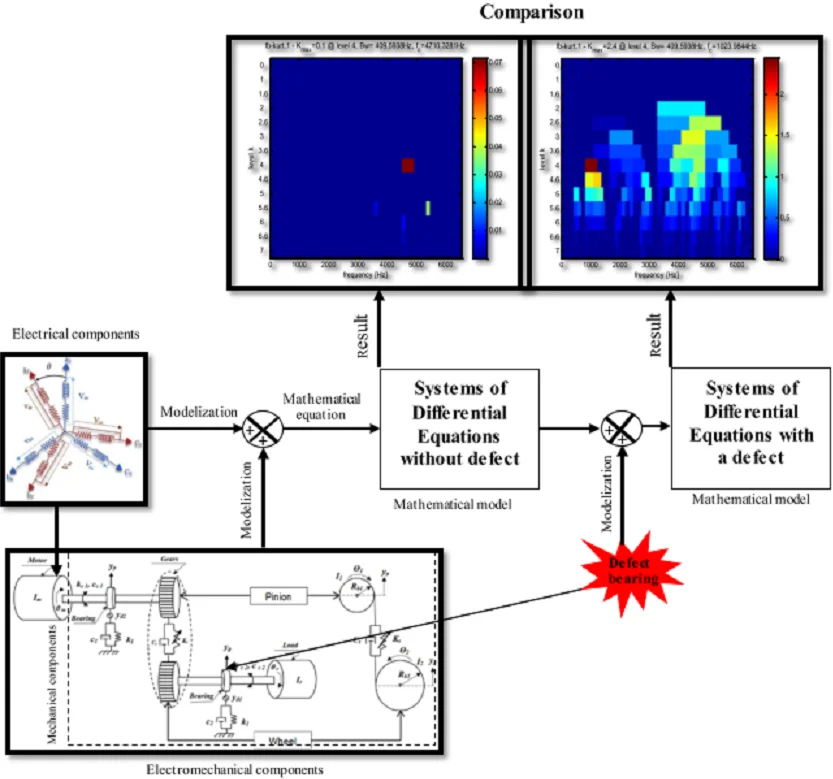

Mathematical modelling of rolling element bearings fault for the diagnosis in the gearbox-induction machine

Inner race fault in bearing suspension is relatively the common fault in induction motors coupled with a gearbox, their detection is feasible by vibration monitoring of characteristic bearing frequencies. However, vibration signals have numerous drawbacks like signal background noise due to external excitation motion, sensitivity due to the installation position and their invasive measurement nature. For this reason, it is necessary to apply an extremely efficient method known as stator current signal analysis which offers significant savings and implementation advantages over traditional vibration monitoring. This paper represents a mathematical model for electromechanical systems and for rolling-element bearing faults to study the influence of mechanical defects on electrical variables (stator current). The novelty in this work involves three contributions: modelling of rolling bearing faults by external forces applied on the electromechanical system; Physical representation of rolling bearing fault allowing the modeling of the studied system functionality and, the influence of mechanical fault (inner race) in the electrical variables (stator current). Simulation results at the end of this paper demonstrate the effectiveness of the proposed mathematical model to detect gearbox’ bearing fault based on the electrical stator current signal with high sensitivity using fast Kurtogram approach.

March 31, 2020

Informatics

Mathematical Models in Engineering

Mathematical results and models specifically applicable to engineering science, technology, and their practical applications across various disciplines

CiteScore

0.2

APC

350 EUR

Best of Theme

Most cited

Research article

December 31, 2018

An intelligent fault diagnosis method of rotating machinery using L1-regularized sparse filtering

By Weiwei Qian, Shunming Li, Jinrui Wang, Zenghui An, Xingxing Jiang

Most cited

Research article

September 30, 2019

Fault diagnosis method for energy storage mechanism of high voltage circuit breaker based on CNN characteristic matrix constructed by sound-vibration signal

By Shutao Zhao, Erxu Wang, Jiawei Hao

Most cited

Research article

April 2, 2020

Artificial neural network based fault diagnostics for three phase induction motors under similar operating conditions

By Abhisar Chouhan, Purushottam Gangsar, Rajkumar Porwal, Christopher K. Mechefske

Most cited

Research article

December 2, 2021

Mathematical modeling of forced oscillations of semidefinite vibro-impact system sliding along rough horizontal surface

By Vitaliy Korendiy, Volodymyr Gursky, Oleksandr Kachur, Volodymyr Gurey, Oleksandr Havrylchenko, Oleh Kotsiumbas

You might also like

Most downloaded

Research Article

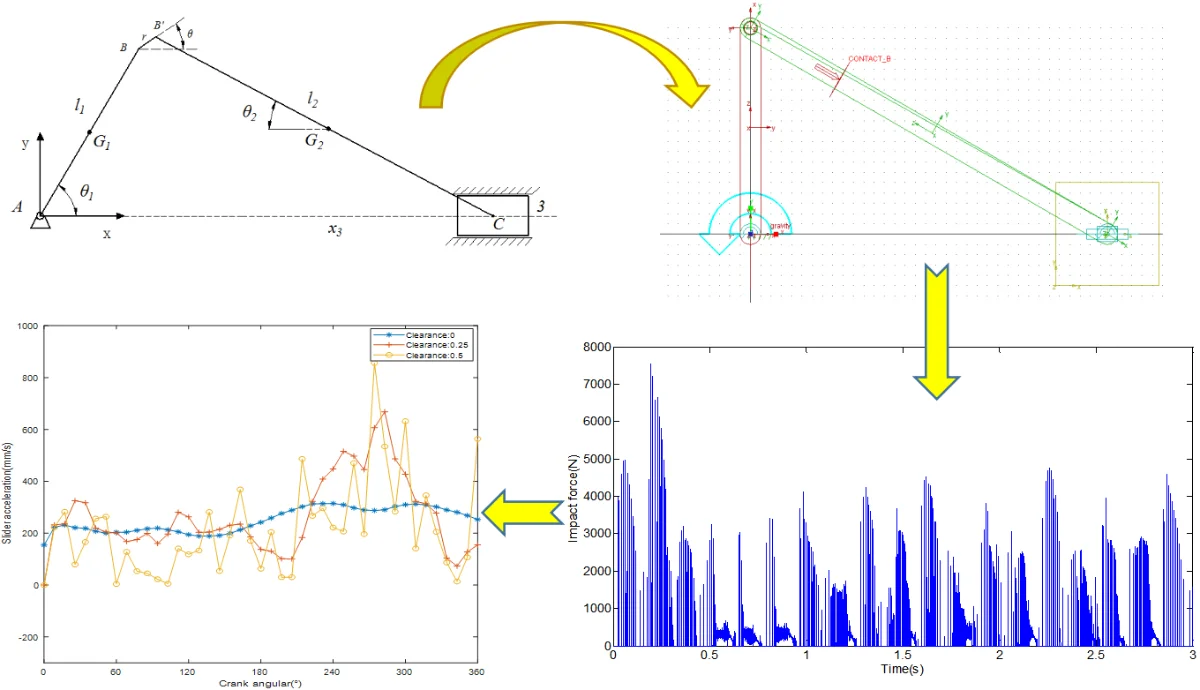

Dynamic analysis of slider-crank mechanism with clearance fault

By Shungen Xiao, Mengmeng Song, Zexiong Zhang

In this paper, the dynamic behavior of the slider-crank mechanism with clearance fault is investigated. The revolute joint with clearance is equivalent to a virtual massless rod, and then the dynamic equation of the crank slider mechanism with clearance is established by the Lagrangian method. In addition, a three-dimensional dynamic model of the crank slider mechanism with clearance is also established by ADAMS. The numerical results show that the clearance affects the displacement and velocity response of the crank-slider mechanism in a weak way, but influences the acceleration response of the mechanism in a significant manner. Due to the existence of the clearance, the revolute joint of the mechanism produces a rub-impact phenomenon, and the larger the clearance, the greater the impact strength. During the rub-impact process, there are three kinds of motion states of separation, collision and contact occur.

November 28, 2019

Applied Mathematics

Most downloaded

Research Article

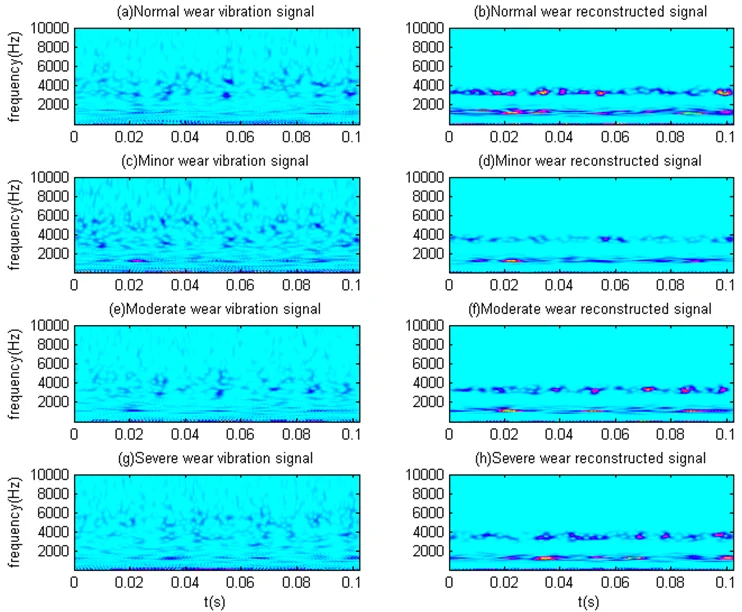

Variational mode decomposition denoising combined with the Euclidean distance for diesel engine vibration signal

By Gang Ren, Jide Jia, Jianmin Mei, Xiangyu Jia, Jiajia Han

Variational mode decomposition (VMD) is a recently introduced adaptive signal decomposition algorithm with a solid theoretical foundation and good noise robustness compared with empirical mode decomposition (EMD). There is a lot of background noise in the vibration signal of diesel engine. To solve the problem, a denoising algorithm based on VMD and Euclidean Distance is proposed. Firstly, a multi-component, non-Gauss, and noisy simulation signal is established, and decomposed into a given number K of band-limited intrinsic mode functions by VMD. Then the Euclidean distance between the probability density function of each mode and that of the simulation signal are calculated. The signal is reconstructed using the relevant modes, which are selected on the basis of noticeable similarities between the probability density function of the simulation signal and that of each mode. Finally, the vibration signals of diesel engine connecting rod bearing faults are analyzed by the proposed method. The results show that compared with other denoising algorithms, the proposed method has better denoising effect, and the fault characteristics of vibration signals of diesel engine connecting rod bearings can be effectively enhanced.

August 15, 2018

Applied Mathematics

Research on unbalance response characteristics of gas turbine blade-disk rotor system

Taken a gas turbine rotor system as the research object, this paper has established dynamical model based on transfer matrix method. Natural vibration characteristics are solved with different transfer matrix models, and are compared with that gotten by finite element method. Then unbalanced response is researched. The effects of eccentric factors are discussed on unbalanced vibration. Furthermore, the application is explored in rotor dynamic balancing. The results show there is much minor deviation between natural frequencies of transfer matrix method and finite element method, and vibration modes of two methods coincide quite well. It illustrates the model established in the research is reliable. For input side of blade-disk rotor, unbalanced vibration occurs more easily in lower frequency. While unbalanced vibration of output side is more sensitive at higher frequency. With the increase of eccentric mass, unbalanced vibration of blade-disk rotor is more heavily, and the displacement rotates around a fixed node. The application of opposite unbalanced mass can decrease the amplitude of vibration in lower frequency. Hence, it can be used to achieve the balance of rotor dynamics. This research provides the theoretical basis and technological fundament for gas turbine rotor dynamics design.

Mathematical modeling of first order process with dead time using various tuning methods for industrial applications

The proposed research involves Mathematical modeling for first order process with dead time using various tuning methods for industrial applications. Different tuning methods are proposed. Proposed method selection depends on plant operating conditions and also depending upon the process dynamics. The PID controller is most widely used for industrial process control. Modeling were developed for modified internal control model [4-6] in this proposed research. The proposed work is the modeling and simulation of three different first order processes with dead time. The standard controller tuning method is used to obtain the steady state response of first order with dead time.