Abstract

The subgrade filling of high-grade highways requires a lot of earth and stone. If the use of fly ash is used for filling, the purpose of reducing the weight of the subgrade and consuming a large amount of industrial solid waste can be achieved. In order to ensure that fly ash has the possibility of filling, it is necessary to systematically study the road geotechnical properties of fly ash. In this paper, the low liquid limit silty silica-alumina fly ash is taken as the research object, and the road geotechnical properties of fly ash are studied through laboratory tests. The results of the compaction test show that the maximum dry density and optimum moisture content have an obvious linear relationship with the increase in the proportion of fly ash. Small, conducive to the stability of the roadbed. The shear strength of fly ash mainly depends on the internal friction angle, which is much larger than that of ordinary clay. The above test conclusions can provide reference for scientific and economical treatment of fly ash subgrade.

Highlights

- The height of capillary water rise and permeability of fly ash are relatively large, and the capillary phenomenon and permeability decrease as the compaction degree increases.

- Under the same conditions, the settlement deformation of fly ash roadbed will be smaller than that of soil roadbed, which is easier to stabilise

- Increasing the amount of fly ash is beneficial to improve the bearing ratio of the roadbed, and it shows a positive correlation with the compaction degree.

1. Introduction

In recent years, with the rapid development of highways, the demand for construction materials is increasing, and the common feature of high-grade highways is that the roadbed is high, and the contradiction between soil extraction for roadbed and agriculture for land is becoming more and more acute. For this reason, people have started to look for reasonable alternatives to soil for road foundations. Among them, fly ash is a kind of micro-fine industrial solid waste with volcanic ash activity in granular form discharged from coal-fired power plants, and fly ash has the characteristics of light self-weight, high strength, low compressibility and good permeability compared with general fine-grained soil, which basically has the potential to be used in highway projects [1-3]. At present, China's coal-fired power plants discharge about 300 million tons of ash each year, if not used, not only restrict the development of the power industry, but also occupy a lot of land, causing dust pollution and other environmental problems.

Practice has proved that fly ash used as roadbed filling material for highways is completely feasible, as a good roadbed filler and inorganic binding material of fly ash, in recent years has been well developed and utilized, widely used in the roadbed and road surface of various grades of highways, basically solving the problem of difficult emission of fly ash from thermal power plants and increasing costs year by year [4-7]. Meng et al. [8] proposed the use of lime and fly ash in the construction of roadbeds on a large scale through the filling technology of the embankment of Qingyin Expressway, which can speed up the project progress, improve the construction quality and save costs. Zhang et al. [9] carried out field tests and theoretical studies on the applicability of fly ash as roadbed filler in highway widening projects, and verified the feasibility and applicability of fly ash as highway widening filler. Tian et al. [10] systematically studied the influence of compaction and moisture content on fly ash and its strength indexes of fly ash roadbed through the demand of roadbed filling for mountainous high-grade highways, and verified the feasibility of fly ash roadbed filling. Ma et al. [11] took fly ash roadbed filling technology as the research background, and discussed the application points of this technology in roadbed construction through the preparation of fly ash roadbed filling construction, fly ash storage and transportation, fly ash paving and shaping and rolling construction, etc. It proved that the application of fly ash roadbed filling construction technology can effectively improve the strength of roadbed, which has an important role in promoting the development of the transportation industry.

However, the chemical and physical properties of fly ash are affected by various factors such as coal type, fineness of pulverised coal, boiler installation, load and combustion conditions, dust collection and conveying and storage methods. Therefore, the physical and chemical properties of fly ash vary from manufacturer to manufacturer [12]. And the small cohesive force of fly ash and the influence of capillary water action, then in turn, has a certain adverse effect on the stability of the roadbed [13]. Therefore, a systematic study on the road geotechnical properties of fly ash is necessary. In order to further investigate the difference between the indicators of pure soil roadbed and pure fly ash roadbed, and to verify the feasibility of fly ash fill roadbed, part of the tests used different amounts of fly ash admixture as fill to study its basic physical properties and mechanical indicators. In order to give full play to the advantages of fly ash and avoid its disadvantages, so as to provide assistance in proposing more comprehensive technical solutions for roadbed design and construction.

2. Experimental

2.1. Raw materials

Fly ash is a special roadbed filler and has strict requirements on raw materials. According to the Highway Roadbed Design Specification [14], the burn loss of fly ash used for highway and primary highway embankment should be less than 20 %, and the particle size of fly ash is between 0.001-1.18 mm, and the content of particles less than 0.075 mm should be more than 45 %. Based on this, the fly ash selected for the test study is Qingdao Zexin material fly ash, without any crushing, sieving and other processing, the colour is dark grey, the factory test report burn loss is not more than 11 %, the content of particles below 0.075 mm is not less than 60 %. The soil used for the test is Weichen-Qingdao Expressway roadbed filling soil.

2.2. Test protocol

The basic properties of fly ash, such as water content, density, burn-off, sulphur trioxide content, activity index and mineral composition, were measured in accordance with the Method of Chemical Analysis of Cement [15] and the Test Procedure for Inorganic Binding Material Stabilization Materials for Highway Engineering [16]. Particle analysis, specific gravity, liquid-plasticity, compaction, capillary water, straight shear, consolidation and bearing ratio (CBR) of fly ash or fine-grained soil were tested in accordance with the test methods required in the Specification for Highway Geotechnical Testing [17]. In order to ensure the reliability of the test results, the number of specimens prepared is strictly in accordance with the relevant specifications and the mean value of the test results with a coefficient of variation of 15 % or less is taken to minimise the test error.

3. Results and discussion

3.1. Basic properties of fly ash

The mineral composition of the fly ash as well as the burn-off, density and specific surface area were measured in accordance with the Test Procedure for Inorganic Binding Material Stabilization Materials for Highway Engineering [16], and the technical indexes were all in line with the technical requirements for fly ash in the Technical Rules for Construction of Road Pavement Base [18], and the CaO content was 3.3 %, so it could be concluded that the fly ash was silica-aluminium fly ash. The fly ash was tested for sulphur trioxide content in accordance with the Method of Chemical Analysis of Cement [15] by the barium sulphate weight method, and the test result was 4.4% > 3.0%, and the test result for the activity index was 61.9 % < 70 %, both of which did not meet the relevant requirements of Fly Ash for Use in Cement and Concrete [19]. The relevant data are shown in Tables 1 and 2.

Because of the fine fly ash particles, the specific gravity bottle method was used to determine the specific gravity of the fly ash as well as the soil. The average specific gravity of a general sandy soil is 2.65, a light sub-clay 2.70, a sub-clay 2.71 and a clay 2.74 [20]. As can be seen in Table 2, the specific gravity of the soil is 2.657 and the specific gravity of fly ash is 2.227, which is significantly lower than the average clay and sandy soil. The main reason for the light weight of fly ash is that fly ash contains carbon particles and some of the fly ash particles are hollow in structure. The plasticity index of fly ash is 9.7 and the plasticity index of soil is 10.2. According to the Specification for Highway Geotechnical Testing [17] and the Engineering Classification Standard for Soil [21], the soil is clayey sand (SC) and the fly ash is in the transition zone between clay and chalk and belongs to low liquid limit chalk (MLS).

Table 1Mineral composition of fly ash

Material | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | Moisture content (%) | Density (g/cm3) | Loss on ignition (%) | Specific surface area (cm²/g) |

Fly ash | 52.4 | 20.5 | 7.2 | 3.3 | 1.1 | 24.6 | 2.224 | 6.9 | 2660 |

Table 2Basic physical properties of fly ash and soil

Material | WL (%) | Wp (%/) | Ip | Proportion | SO3 (%) | Activity index |

Fly ash | 40.7 | 31.0 | 9.7 | 2.227 | 4.4 | 61.9 |

Soil | 31.8 | 21.6 | 10.2 | 2.657 | / | / |

The relationship between dry density and moisture content of fly ash and soil was determined using compaction tests to determine the maximum dry density and the corresponding optimum moisture content. In this paper, heavy compaction tests on fly ash, composite soil with mass ratio fly ash: soil = 70:30, fly ash: soil = 50:50, fly ash: soil = 30:70 and pure soil were carried out to finally determine the optimum moisture content and maximum dry density at different blending ratios.

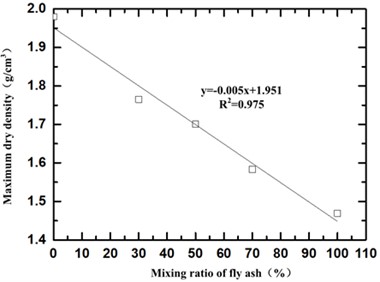

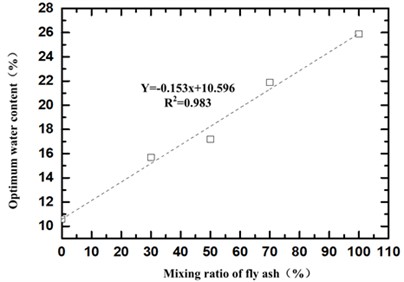

Fig. 1Corresponding relationship between fly ash mixing ratio and maximum dry density and optimum water content

The correspondence between the different blending ratios of fly ash and the maximum dry density and optimum moisture content is shown in Fig. 1. The maximum dry density and optimum moisture content of fly ash and pure soil are 1.469 g/cm3 and 25.9 % and 1.980 g/cm3 and 10.6 % respectively. The compaction characteristics of fly ash have typical non-cohesive soil properties and the ideal compaction density can be obtained within the range of 18 %-35 % water content. In addition, as fly ash is less dense than soil, the maximum dry density gradually decreases and the optimum water content gradually increases as the percentage of fly ash participation increases, showing an obvious linear relationship.

3.2. Fly ash mechanical properties

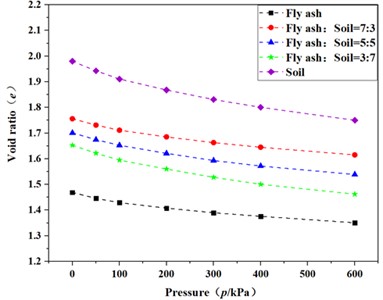

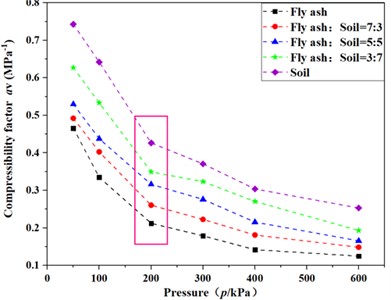

According to the results of compaction tests with different fly ash admixtures, the specimens were prepared according to the optimum moisture content and 93 % compaction degree, and the moisture content of the specimens was tested after the tests and did not change much from the optimum moisture content. The pore ratio and the compression coefficient with pressure are shown in Fig. 2. It can be found that the pore ratio and the compression coefficient decrease gradually with the increase of fly ash admixture, and the pore ratio and the compression coefficient show an obvious decreasing trend with the increase of pressure. The compression coefficient in the pressure range from 100 to 200 kPa was used to evaluate the consolidation effect, and the compression coefficient showed a negative correlation with the water content and a positive correlation with the dry density. deformation is very small. The water and gas inside the particles are not easily discharged during compression, so although the specific gravity of fly ash is small, it is not very compressible. Due to the small compression coefficient, the settlement of the roadbed after filling is also small, i.e. under the same conditions, the settlement deformation of the fly ash roadbed will be smaller than that of the soil roadbed, which is easier to stabilise.

Fig. 2Variation curves of fly ash void ratio and compressibility with pressure under different blending ratios

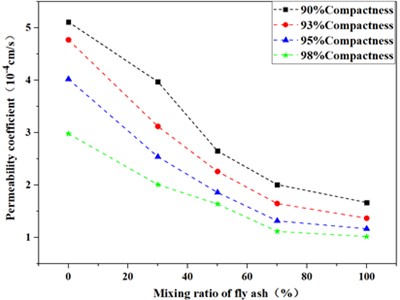

According to the particle analysis test, the fly ash in this project are all fine-grained soils. According to the requirements of the Highway Geotechnical Test Procedure, the variable head permeability test was used to study the permeability of fly ash, and the permeability coefficients of fly ash under different compaction degrees (90 %, 93 %, 95 % and 98 %) were studied at different blending ratios, and the relevant data are shown in Fig. 3(a). It can be found that as the percentage of fly ash increases, the permeability coefficient of the powder gradually decreases. In addition, the greater the compaction, the worse the permeability.

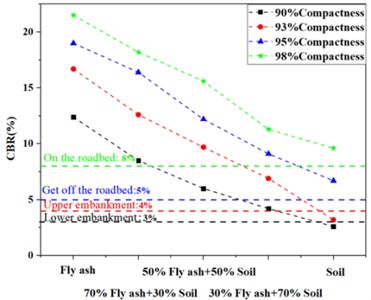

CBR tests were carried out on pure fly ash, fly ash: soil = 70:30, fly ash: soil = 50:50, fly ash: soil = 30:70 composite soil and pure soil respectively. The results are shown in Fig. 3(b). The CBR values were found to decrease with the decrease of fly ash mixture, which is consistent with the report that the bearing ratio of pure soil does not meet the requirement of adding fly ash to improve the bearing ratio [22-24]. The CBR value is significantly increased with the increase of compaction. According to the Technical Specification for Highway Roadbed Construction [25] the minimum bearing ratio of fill roadbed fill is required, in which 8 % for the upper roadbed, 5 % for the lower roadbed, 4 % for the upper embankment and 3 % for the lower embankment of high speed and primary roads. Therefore, in engineering applications, the amount of fly ash admixture and compaction can be adjusted to meet the requirements of the bearing ratio of various parts of the roadbed.

Fig. 3Permeability coefficient and CBR of fly ash under different compaction degrees

a)

b)

4. Conclusions

In this paper, the geotechnical properties of fly ash for road use were investigated through indoor tests with bulk solid waste fly ash as the research object, with a view to providing a scientific basis for practical highway road foundation projects. The conclusions drawn from the study are as follows:

1) The fly ash selected for study in this paper is a low liquid limit fly ash, a silica-alumina fly ash, with a specific gravity of 2.27 and poor grading performance.

2) The compaction characteristics of fly ash are typical of non-cohesive soils. As the density of fly ash is smaller than that of soil, the maximum dry density gradually decreases and the optimum moisture content gradually increases as the proportion of fly ash is increased, showing an obvious linear relationship.

3) The height of capillary water rise and permeability of fly ash are relatively large, and the capillary phenomenon and permeability decrease as the compaction degree increases.

4) Fly ash is a pulverized soil and its compression coefficient is small, and the settlement of the roadbed after it is filled is also small. That is, under the same conditions, the settlement deformation of fly ash roadbed will be smaller than that of soil roadbed, which is easier to stabilise.

5) Increasing the amount of fly ash is beneficial to improve the bearing ratio of the roadbed, and it shows a positive correlation with the compaction degree.

References

-

R. Lei, D. S. Fu, G. Li, X. Sun, C. Yuan, and H. Zheng, “Research progress of fly ash comprehensive utilization,” Clean Coal Technology, Vol. 19, No. 3, pp. 106–109, 2013, https://doi.org/10.13226/j.issn.1006-6772.2013.03.029

-

G. Y. Liu, “Discussion on the present situation and development perspective of comprehensive utilization of fly ash,” Journal of Library and Information Science, Vol. 20, No. 19, pp. 167–170, 2019.

-

L. Zhang et al., “Progress and prospect of comprehensive utilization of fly ash,” Development Guide to Building Materials, Vol. 19, No. 24, 2021.

-

W. Cui and X. Zheng, “Study on reinforcement technique of embankment of highway crossing area of fly ash setting basin science,” Technology and Engineering, Vol. 19, No. 24, pp. 1–16, 2021.

-

X. S. Zhuang, W. K. Peng, and J. B. Wu, “Study of cracking characteristics and influencing factors for fiyash-treated expanxive soil in dehydration process,” Science Technology and Engineering, Vol. 17, No. 6, pp. 252–258, 2017.

-

Y. Hao and S. J. Yan, “Analysis on construction technology of fly ash subgrade filling of expressway,” Communications Science and Technology Heilongjiang, Vol. 35, No. 9, p. 35, 2012.

-

R. Li, “Stability analysis of roadbed slope reinforced with fly ash,” Fly Ash Comprehensive Utilization, Vol. 20, No. 4, pp. 64–67, 2019.

-

F. S. Meng, “Mixing quicklime and fly ash to treat high plastic finger soil to fill roadbed,” (in Chinese), Highways and Transportation in Inner Mongolia, Vol. 1, pp. 18–20, 2005.

-

X. L. Zhang and H. Y. Hu, “Applicability of fly-ash for high embankment in widening engineering,” (in Chinese), Journal of Chongqing Jiaotong University (Natural Science), Vol. 33, No. 2, pp. 58–62, 2014.

-

X. B. Tian, J. M. Wei, and J. Zhang, “Analysis and research on influencing factors of fly ash subgrade strength characteristics,” Journal of China and Foreign Highway, Vol. 32, No. 5, pp. 33–35, 2012.

-

Y. H. Ma, “Subgrade construction fly ash subgrade filling construction technology,” (in Chinese), Communications Science and Technology Heilongjiang, Vol. 42, No. 8, pp. 49–50, 2019.

-

M. B. Chen and G. Chen, “Difference of fly ashes and application in coal minek,” Coal Science and Technology, Vol. 34, No. 7, pp. 72–75, 2006.

-

Y. Liu, Y. L. Li, and L. Yang, “Study on the stability test of improved soft soil roadbed with fly ash,” Fly Ash Comprehensive Utilization, Vol. 5, pp. 96–98, 2018.

-

“Highway Roadbed Design Specification,” JTG D30-2004, Beijing: China Communication Press, 2004.

-

“Method of Chemical Analysis of Cement,” GB/T 176-2017, Beijing: Standards Press of China, 2017.

-

“Test Procedure for Inorganic Binding Material Stabilization Materials for Highway Engineering,” JTG E51-2009, Beijing: China Communication Press, 2009.

-

“Specification for Highway Geotechnical Testing,” JTG 3430-2020, Beijing: China Communication Press, 2020.

-

“Technical Rules for Construction of Road Pavement Base,” JTG/T F20-2015, Beijing: Standards Press of China, 2015.

-

“Fly Ash for Use in Cement and Concrete,” GB/T 1596-2017, Beijing: Standards Press of China, 2017.

-

S. N. Sui, L. Hai, and R. P. Zeng, “Test analysis of the fly ash’s geotechnical properties for road use,” Journal of Materials Science and Engineering, Vol. 35, No. 2, pp. 278–283, 2017, https://doi.org/10.14136/j.cnki.issn1673-2812.2017.02.022

-

“Engineering Classification Standard for Soil,” GB/T 50145-2007, Beijing: Standards Press of China, 2007.

-

Z. Q. Li, “Reinforcement method of expressway roadbed crossing fly ash settling basin,” Science Technology and Engineering, Vol. 19, No. 17, pp. 307–313, 2019.

-

H. Niu, “Mechanical properties of Shanghai soft clay mixed with fly-ash and lime fly-ash,” Journal of Disaster Prevention and Mitigation Engineering, Vol. 40, No. 6, pp. 992–1000, 2020, https://doi.org/10.13409/j.cnki.jdpme.2020.06.019

-

R. Z. Li, “Experimental Research on Bearing Ratio (CBR) in Expressway Construction,” TranspoWorld, Vol. 25, pp. 59–61, 2020.

-

“Technical Specification for Highway Roadbed Construction,” JTG/T 3610-2019, Beijing: Standards Press of China, 2019.

About this article

The authors have not disclosed any funding.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.