Abstract

A comparison between the two strategies: secondary traditional mixing technology and secondary vibratory mixing technology is proposed based on aggregate sieving, cement EDTA titration and unconfined compressive strength tests to explore the influence of the uniformity and strength of cement stabilized macadam mixture in the paper. The results show that when the secondary vibratory mixing technology is adopted: (1) the standard deviations and coefficients of variation of the passing rates of key sieves of 19 mm, 13.2 mm, 9.5 mm, 4.75 mm and the cement dosage titration results decrease significantly, and the mixing uniformity of the mixture is significantly improved; (2) the 7-day and 28-day unconfined compressive strengths of the mixtures are significantly improved while the strength standard deviations and coefficients of variation are reduced, with an obvious trend along with the extension of the curing time (within 28 days).

Highlights

- The passing rate of the key sieve holes of the cement stabilized macadam mixture by secondary traditional mixing process and the standard deviation and coefficient of variation after the cement content titration test are relatively small; but with secondary vibratory mixing process, the standard deviation and coefficient of variation are further reduced, showing a better mixing uniformity.

- Compared to the secondary traditional mixing, the average and representative values of unconfined compressive strength of the secondary vibratory mixing process with 7-day and 28-day are significantly improved, and the standard deviation and coefficient of variation of strength are obviously lower.

- In construction and production works, secondary vibratory mixing process is recommended.

1. Introduction

Cement stabilized macadam mixture is one of the semi-rigid materials commonly used in China’s high-grade road base. And the strength of the cement stabilized macadam mixture is the key technical analysis indicator and has a significant impact on its durability in use [1, 2]. The mixing technology influences the dispersing and wrapping effects of cement, water and aggregate. And it fundamentally affects the mechanical properties and road performance of the cement stabilized macadam mixture [3-5]. A secondary mixing technology was adopted in Xudong Wang, et al. [6]. The mixing properties (dispersion uniformity and wrapping effect) of the cement stabilized macadam mixture were improved by extending the mixing time and its strength and durability of cement stabilized macadam mixture were effectively improved. A new vibratory mixing technique on cement stabilized macadam mixture has come up during the last two years, objecting in enhancing the strength by improving the uniformity of the material and stimulating the material potential to a higher extent [7-10]. Thus, we combine the secondary traditional mixing and vibratory mixing technologies based on scientific studies and engineering application projects, and study the effect of the improved secondary mixing process on mixing effect and strength of the cement stabilized macadam mixture, which provides supports for the promotion and application, and is also a useful supplement to the research results in the field of cement stabilized semi-rigid base [11-15].

2. Vibratory mixing technology principle

Vibratory mixing technology is based on the traditional ordinary static mixing with the addition of vibration process, realized by joint action of the forced mixing by blades and the continuous vibration from the mixing cylinder lower recumbent shaft. The performance improvement of the cement stabilized macadam mixture by the vibratory mixing technology can be described in the ways below.

A high-frequency (more than 1500 times per minute) elastic wave can be released continuously by the vibration of the lower recumbent shaft. The elastic wave transfers the vibration energy to all directions in real time. This can make the cement stabilized macadam mixture material stay in a long-term vibration state, especially influence the cement particles, water molecules and fine aggregates significantly, effectively destroy cement and cement mortar agglomerates and make the cement stabilized macadam mixture material more uniformly distributed on the macro and micro levels.

3. Comparison scheme and aggregate composing design

3.1. Comparison scheme of mixing process

This paper sets up the comparison strategy based on the mixing plant construction. The mixing process on the cement stabilized macadam mixture base material is designed with two mixing cylinders in series, and the difference is whether the second mixing is done by vibratory mixing or not, as shown in Table 1.

Table 1Comparison scheme of the mixing process

First mixing | Second mixing | |

Scheme 1 | 800T Traditional static mixing | 800T Vibratory Mixing |

Scheme 2 | 800T Traditional static mixing | 800T Traditional static mixing |

3.2. Aggregate composing design

A relatively better grading is used in this paper for a better and clear comparison results on the uniformity of the cement stabilized macadam mixture under different mixing processes, and to avoid the adverse effects caused by the grading. The skeleton interlocking structure is adopted, and the CA, FAc and FAf parameters of the Bailey method are used for the performance evaluation of the designed graded skeleton interlocking structure. CA evaluates the interlocking condition of the coarse aggregate in the aggregates; FAc evaluates the interlocking and filling effects of coarse and fine aggregates; FAf evaluates the interlocking and filling effects of the finest aggregate. According to reference, the recommended values of the above parameters are: CA: 0.70- 0.85, FAc: 0.35-0.50, FAf: 0.35-0.50 for the grading with the nominal maximum particle size of 26.5 mm.

Therefore, in this paper, we choose the cement: P.C32.5R with 4.5 %, the nominal maximum particle size of aggregate: 26.5 mm. The grading design results are shown in Table 2 while the corresponding grading test results are shown in Table 3. And the cross-sectional structure of the design grading specimen is shown in Fig. 1, from which we can see that the designed grading structure does have good interlocking effect.

Table 2Passing rate of main sieve holes of the design grading.

Size of the sieve holes (mm) | 26.5 | 19 | 16 | 13.2 | 9.5 | 4.75 | 2.36 | 1.18 | 0.6 | 0.3 | 0.15 | 0.075 |

Upper limit | 100 | 89 | 75 | 66 | 55 | 37 | 28 | 20 | 15 | 12 | 10 | 4 |

Lower limit | 9 | 72 | 60 | 50 | 44 | 27 | 16 | 12 | 7 | 5 | 4 | 2 |

Construction grading (%) | 96.8 | 77.2 | 69.0 | 62.3 | 48.8 | 33.9 | 20.7 | 15.2 | 10.4 | 7.2 | 4.9 | 3.3 |

Table 3Gradation test results

Parameter | CA | FAc | FAf |

Suggested value range | 0.70-0.85 | 0.35-0.50 | 0.35-0.50 |

Test value | 0.77 | 0.45 | 0.47 |

Fig. 1The cross-sectional structure of the specimen

4. Material mixing uniformity

4.1. Test method

Mixing uniformity influences badly on the strength, crack resistance, scouring resistance and durability of cement stabilized macadam semi-rigid base. Using the screening test and cement EDTA titration, this paper analyzes the mixing uniformity taking the average value, standard deviation and coefficient of variation of the key sieves’ passing rate of the aggregate and the cement dose test results as mathematical statistics. The statistical results of the screening test reflect directly the fluctuation of construction gradation and indirectly the macro uniformity of the aggregate distribution while the statistical results of cement EDTA titration test reflect the uniformity of cement dispersion in cement stabilized macadam mixture which shows the micro uniformity to a certain extent.

4.2. Test result analysis

4.2.1. Aggregate mixing uniformity

According to the two mixing process schemes designed, the cement stabilized macadam mixtures are taken respectively after the pave work for water washing and screening test. Eight groups of parallel tests are carried out in each mixing process, and the sampling interval is 15 min. The passing rates of sieve holes of 19 mm, 13.2 mm, 9.5 mm and 4.75 mm and the average passing rates, standard deviation (SD) and coefficient of variation (CV) are calculated and listed in Table 4.

Table 4Statistical results of the pass rates of key sieve holes in the screening test

Passing rate (%) | Average value (%) | SD | CV (%) | |||||||||

Parallel test group | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | ||||

Scheme 1 | 19 mm | 78.1 | 82.4 | 76.4 | 74.2 | 81.5 | 81.2 | 76.4 | 75.3 | 78.2 | 2.925 | 3.7 |

13.2 mm | 63.5 | 59.2 | 62.6 | 65.1 | 66.3 | 59.8 | 66.1 | 63.6 | 63.3 | 2.494 | 3.9 | |

9.5 mm | 50.4 | 47.2 | 48.6 | 51.2 | 50.5 | 49.2 | 49.9 | 48.2 | 49.4 | 1.258 | 2.5 | |

4.75 mm | 34.2 | 33.8 | 33.1 | 32.9 | 35.2 | 34.2 | 36 | 33.5 | 34.1 | 0.983 | 2.9 | |

Scheme 2 | 19 mm | 81.3 | 73.8 | 72.7 | 83.2 | 75.6 | 73.9 | 79.1 | 81.9 | 77.7 | 3.903 | 5.0 |

13.2 mm | 62.6 | 64.8 | 65.7 | 58.4 | 63.1 | 59.5 | 60.4 | 57.8 | 61.5 | 2.757 | 4.5 | |

9.5 mm | 51.2 | 48.5 | 48.8 | 52.7 | 51.5 | 45.1 | 46.7 | 51.3 | 49.5 | 2.476 | 5.0 | |

4.75 mm | 32.3 | 35.5 | 33.9 | 29.7 | 36.2 | 34.5 | 35.3 | 36.4 | 34.2 | 2.115 | 6.2 | |

As shown in Table 4, the average passing rates of the same sieve hole in schemes 1 and 2 are close to each other and both close to the designed passing rates. It certifies that the quality control on the cement stabilized macadam base aggregate is relatively stable, which ensures the overall stability of the construction grading, and also provides a good basis for the comparison test.

In general, the SDs and CVs of the four key sieve holes’ passage rates of the two mixing process schemes are at a relatively low level, and the CVs range basically between 2-7 %. It shows that the secondary mixing process with two mixing cylinders in series improves the mixing uniformity of the cement stabilized macadam mixture.

Compared to the traditional mixing in scheme 2, the SDs and CVs of all key sieve holes in scheme 1 decrease, i.e., the CVs of the sieve holes of 19 mm and 13.2 mm decrease by 26 % and 13 % respectively while 9.5 mm and 4.75 mm sieve holes decrease by 50 % and 53 % respectively. The results show that the vibratory mixing process improves further the uniformity of aggregate distribution, and the smaller the particle size of aggregate is, the more obvious the improvement is. It also indicates indirectly that the non-uniformity mixing of the cement stabilized macadam mixture is more obvious in the aggregates with smaller particle size due to bonding mass and other reasons.

4.2.2. Cement dispersion uniformity

The number of parallel test groups, sampling position and time interval of the cement EDTA titration test are the same as those of aggregate screening test. The results of cement content titration test of the two mixing process schemes, and the statistical results of average cement contents, SDs and CVs are shown in Table 5.

The statistical results of the cement titration test in Table 5 show that the mean value of cement dosage titration results of the two processes is relatively close. Within the situation of the overall low SD and CV (4-7 %), the SDs and CVs are further reduced by Scheme 1 (in which vibratory mixing is used during the second mixing), where SVs decrease by 34 % and CVs decrease by 36 %. These results show that although the cement dispersion in the cement stabilized macadam mixture with the secondary mixing process is relatively uniform and the overall variation level is low, the agglomeration phenomenon of cement slurry is eliminated to a greater extent with continuous vibrations, so that the variation level of cement content is lower and the cement dispersion is more uniform.

Table 5Statistical results of cement content titration test

Cement content (%) | Average value (%) | SD | CV (%) | ||||||||

Parallel test group | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | |||

Scheme 1 | 4.4 | 4.7 | 4.3 | 4.6 | 4.5 | 4.7 | 4.2 | 4.7 | 4.5 | 0.183 | 4.1 |

Scheme 2 | 3.9 | 4.4 | 4.8 | 4.2 | 4.5 | 4.1 | 4.6 | 4.6 | 4.4 | 0.280 | 6.4 |

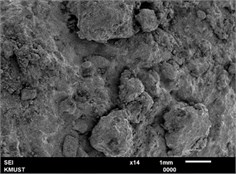

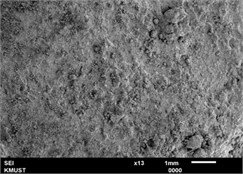

4.2.3. Scanning electron microscope (SEM) analysis

The micro morphology of cement stabilized macadam mixture can be clearly observed by scanning electron microscope, and the influence of mixing mode on the hydration reaction of cement stabilized macadam mixture can be compared and analyzed from the micro level, as shown in Fig. 2.

Fig. 2Bonding state between aggregate and cement

a) Non vibration mixing

b) Vibration mixing

By analyzing the bonding state between aggregate and cement in the mixture of the two mixing methods, it is found that the cement slurry on the surface of the aggregate in the vibration mixing mixture adheres evenly, and there is almost no agglomeration; However, the cement slurry on the surface of aggregate without vibration mixing has obvious agglomeration phenomenon.

5. Strength and construction uniformity

5.1. Test scheme

Strength is the key index of the cement stabilized semi-rigid base, which directly affects the bearing capacity of the base. In Technical Guidelines for Construction of Highway Roadbases (JTG/T F20-2015), the basic strength requirements on cement stabilized semi-rigid base are also higher than before, and it shows the importance of strength. Construction uniformity has a great influence on the variation level of strength and the durability of road structure [20]. This also shows the importance of strength and construction uniformity for cement stabilized semi-rigid base. The designed comparison and construction schemes are shown in Table 6, where the same rolling and regeneration process are used.

Table 6Comparison and construction schemes of the mixing processes

Mixing process | Construction section/Length/Layer | Cement content (%) | Test index (MPa) | Statistical index |

Scheme 1 | K1+500~K2+500/1 km/Left lower base | 4.5 | Unconfined compressive strength | Strength average, value SD, CV, Strength representative value |

Scheme 2 | K1+500~K2+500/1 km/Right lower base |

5.2. Test results analysis

After 7-day and 28-day regeneration processes, nine groups of core samples are randomly drilled in the sections the two mixing process schemes are implemented, and cut into standard specimens with a height diameter ratio of 1:1. The samples’ unconfined compressive strength, SD, CV and the strength representative value with 95 % guarantee rate are tested. The results are shown in Table 7.

In Table 7, the average and representative values of the 7-day and 28-day unconfined compressive strengths of Scheme 1 (second mixing with vibratory mixing process) are greater than those of Scheme 2, and the SVs and CVs of the strengths of the nine sets of core samples are smaller than those of Scheme 2. It shows that the second mixing with vibratory mixing process increases the strength of cement stabilized macadam mixture obviously, reduces the level of SV and improves the construction uniformity. Therefore, vibratory mixing process is recommended to be applied as the second mixing process between the two mixing units in series during construction and production works.

Table 7Tested statistical results of unconfined compression strength

Time | Scheme | Ultimate load (KN) | Average value (MPa) | SD | CV (%) | Representative value (MPa) | ||||||||

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | ||||||

7d | Scheme 1 | 135.24 | 115.52 | 141.22 | 136.35 | 120.80 | 112.53 | 126.06 | 123.22 | 116.49 | 7.1 | 0.578 | 8.2 | 6.1 |

Scheme 2 | 98.13 | 94.72 | 102.21 | 67.36 | 101.29 | 105.59 | 105.92 | 115.19 | 72.15 | 5.6 | 0.712 | 12.8 | 4.5 | |

28d | Scheme 1 | 146.25 | 151.44 | 136.88 | 142.16 | 142.14 | 159.69 | 137.94 | 135.66 | 144.74 | 8.2 | 0.434 | 5.3 | 7.4 |

Scheme 2 | 115.11 | 121.56 | 124.67 | 115.71 | 101.17 | 99.91 | 96.69 | 112.20 | 112.06 | 6.3 | 0.553 | 8.8 | 5.4 | |

6. Conclusions

This paper compares the effects of secondary ordinary mixing process and secondary vibratory mixing process on the mixing uniformity, strength and construction uniformity of cement stabilized macadam mixture, and the following conclusions are obtained:

1) The passing rate of the key sieve holes of the cement stabilized macadam mixture by secondary traditional mixing process and the standard deviation and coefficient of variation after the cement content titration test are relatively small; but with secondary vibratory mixing process, the standard deviation and coefficient of variation are further reduced, showing a better mixing uniformity.

2) Compared to the secondary traditional mixing, the average and representative values of unconfined compressive strength of the secondary vibratory mixing process with 7-day and 28-day are significantly improved, and the standard deviation and coefficient of variation of strength are obviously lower.

3) In construction and production works, secondary vibratory mixing process is recommended.

References

-

A.-M. Sha, “Material characteristics of semi-rigid base,” (in Chinese), Chinese Journal of Highway and Transport, Vol. 21, No. 1, pp. 1–5, Jan. 2008.

-

Hu Yong-Fen, “Quality control of cement stabilized macadam base,” (in Chinese), Xi’an, Chang’an University, 2008.

-

F. Wang, “Research on design and road performance of skeleton-dense cement stabilized crush stone aggregate grading,” (in Chinese), Wuhan, Wuhan Institute of Technology, 2017.

-

H. Li, X. Zhang, G. Liu, and J. Tian, “Comparative application of skeleton dense and suspended dense cement stabilized macadam in Dengfeng Ruzhou section of Jiaotong Expressway,” (in Chinese), Highway Transportation Technology (Application Technology Version), Vol. 11, No. 8, pp. 81–83, 2015.

-

H. Xie, “Application of skeleton dense cement stabilized macadam base in Yun Zhan Expressway,” (in Chinese), Highway, Vol. 63, No. 9, pp. 271–274, 2018.

-

J. Liu, “The study on cracking-resistant crushed stone base stabilized with cement used in highway,” (in Chinese), Highway Engineering, Vol. 38, No. 6, pp. 173–178, 2013.

-

J. Sima, X. Li, and H. Li, “Analysis on key points of construction quality control and mix proportion design of cement stabilized crushed stone in expressway,” (in Chinese), Highway Engineering, Vol. 42, No. 6, pp. 219–222, 2017.

-

X. Wang, “Key issues in the revision of the detailed rules – interpretation of the technical guidelines for construction of highway roadbases,” (in Chinese), China Highway, Vol. 9, pp. 68–69, 2016.

-

R. Li et al., “Comparative study on strength performance of cement stabilized gravel mix under vibration stirring,” (in Chinese), Journal of Chongqing Jiaotong University (Natural Science Edition), Vol. 36, No. 11, pp. 33–36, 2017.

-

S. Ma, “Application of vibration mixing cement stabilized macadam in Beijing Xinjiang Expressway pavement,” (in Chinese), Road Machinery and Construction Mechanization, Vol. 34, No. 11, pp. 100–102, 2017.

-

L. Zhang, X. Kong, and Z. Feng, “The development and industrial tests of vibratory mixing cement stabilized macadam mixer,” (in Chinese), Journal of Guangxi University (Natural Science Edition), Vol. 40, No. 5, pp. 1155–1161, 2015.

-

L. Zhang, “Research on concrete vibration mixing mechanism and industrial application,” (in Chinese), Xi’an, Chang’an University, 2013.

-

X. Kong, P. Tan, Y. Dong, and L. Lin, “Industrial experimental study on stabilized soil vibrating mixer,” (in Chinese), Road Machinery and Construction Mechanization, Vol. 33, No. 6, pp. 37–40, 2016.

About this article

The research was funded by the Science and Technology Project of Department of Transport of Yunnan Province (YunJiaoKeJiao(2016)140(B)).