Abstract

This paper examines vibration behavior of ball bearings dispersed by solid as a function of contamination of lubricant. Experimental tests were performed using SKF 6004 deep groove ball bearing, dispersed with different contaminants particles. Silica sand with different particle sizes, copper (Cu micro particles), poly methyl methacrylate (PMMA), low-density polyethylene (LDPE), and polyamide (PA), all at five concentration levels were used to disperse the lubricant. The contaminants concentration as well as the carbon nanotubes (CNTs) concentration is varied as 1, 2, 3, 4, and 5 wt. %. It was found that as the contaminants particles size and concentration increased, the corresponding acceleration values also increased up to certain limit. Furthermore, the vibration amplitudes decrease due to the increase of the copper concentration. The vibration amplitude was improved due to increase of concentration of carbon nanotubes CNTs.

1. Introduction

Antifriction bearings are the most critical parts in rotating machinery. Main function of these bearings depends on the smooth and quiet running of the roller elements. The behavior of the roller elements have a significant effect on bearing performance. Solid contaminants are denting of the bearing raceways and roller elements. Solid contaminants may be the cause of bearing failure. Therefore, the dynamic behavior of antifriction bearing may be monitored using vibration measurements and wear debris analysis, [1, 2].

Influence of contaminants in the grease of the rolling bearing was investigated using the acoustic emission, [3]. It was found that, small size contaminant particles generated a higher acoustic emission pulse count level than large size particles. The behavior of lubricant contamination by solid Particles on the vibration signals of roller bearings was investigated. The experimental tests were performed with applied radial Load was 10 % of the bearing nominal load. The roller bearings NU205 was used, which lubricated with mineral oil of different viscosity grades, [4, 5]. Quartz powder in three concentration levels and different particle sizes was used to contaminate the oil, [6, 7]. The dolomite powder in three concentration levels and different particle sizes was used to contaminate the grease with deep groove ball bearings, [8]. Different materials such as Silica, metal-burr, dolomite-powder, iron-ore, and sawdust, all at three concentration levels and different particle sizes were used to contaminate the lubricant, [9, 10].

Al2O3 nanoparticles as lubricating oil additives were investigated, and it is showed that the friction coefficient was decreased by 40-50 % in comparison with the solution without Al2O3 particles, [11, 12]. Modified SiO2 nanoparticles as lubricating oil additives had better tribological properties in terms of load-carrying capacity, anti-wear and friction reduction, [13, 14]. Al2O3/SiO2 composite nanoparticles were expected to be more interesting when they were used as lubricating oil additives [15-18]. Modified Al2O3/SiO2 composite nanoparticles as lubricating oil additives were investigated by four-ball and thrust-ring tests in terms of vibration and coefficient of friction. It is found that their anti-wear and anti-friction performances are better than those of pure Al2O3 or SiO2 nanoparticles, [19]. The vibration characteristics of ball bearing supplied with nano-copper oxide (CuO) mixed lubricant was investigated. The results show a reduce of 41 % vibration amplitude while using 0.2 % (W/V) CuO nanoparticles in outer case defected compared to pure lubricant, [20].

The objective of this work is to investigate vibration behavior when ball bearings are dispersed by solid contaminates. Experimental tests were performed in SKF 6004 deep groove ball bearing, contaminated with different contaminants particles. The effect of carbon nanotubes CNTs as lubricant additives were investigated. The contaminants concentration as well as the carbon nanotubes CNTs concentration is varied as 1, 2, 3, 4, and 5 wt. % of the solid lubricant.

2. Materials and methods

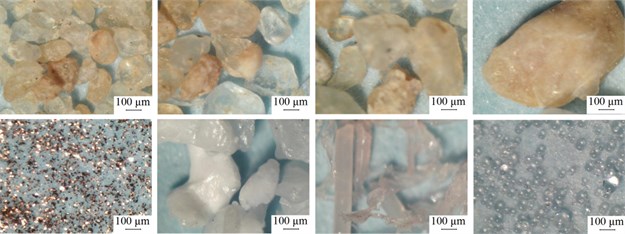

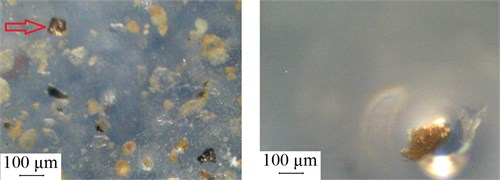

The bearing type that has be used in this study is a single row deep groove ball bearing SKF 6004. Lithium grease without additive was used as a basic lubricant. Generally different materials such as silica sand of (0-150 μm) “A”, (150-300 μm) “B”, (300-600 μm) “C”, and (600-1400 μm) “D”. particle sizes, copper (Cu micro particles), poly methyl meth acrylate (PMMA), low density polyethylene (LDPE), and polyamide (PA), all at five concentration levels were used to disperse the grease. The morphology of the used contaminants particles is shown in Fig. 1.

Carbon nanotubes CNTs were of the size range outside diameter: >50 nm, inside diameter: 5-15 nm, and length: 5-20 um. Carbon nanotubes CNTs was added to the lubricant. The contaminants concentration as well as the carbon nanotubes CNTs concentration is varied as 1, 2, 3, 4, and 5 wt. % of the lithium grease.

Fig. 1The morphology of the contaminants particles

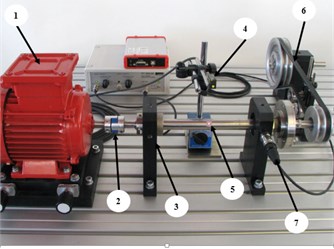

An experimental setup is employed in this work with the purpose of obtaining the vibration response related to different testing conditions of the bearing element contacts. Fig. 2 schematically shows the tested ball bearing in the rig. An optical encoder is used for the speed measurement. An elastic claw coupling is utilized to damp out the high-frequency vibration generated by the motor. Two ball bearings are fitted into the solid housings. Accelerometers (IMI Sensors- 603C01) are mounted on the housing of the tested bearing to measure the vibration signals along two directions. Vibration signatures are analyzed in terms acceleration values at particular defect frequencies and also in terms of overall root mean square (RMS) values.

Fig. 2Schematic representation of the test ring: 1 – drive unit, 2 – Elastic claw coupling, 3 – bearing block, 4 – shaft with reflective mark, 5 – reference sensor, 6 – belt drive, 7 – acceleration sensor

Vibration was determined through the processing and analysis of bearing radial vibration data, obtained from each of the lubrication conditions, during 1.5 hr. of test run for temperature stabilization and under several bearing shaft speeds. The applied radial load was 20 % of the bearing basic load. Through root mean square (RMS) analysis of the vibration signals, it was possible to identify specific frequency bands modulated by the change in contaminants concentration and the Carbon nanotubes CNTs concentration

3. Results and discussion

3.1. Analysis of contaminant particles adding

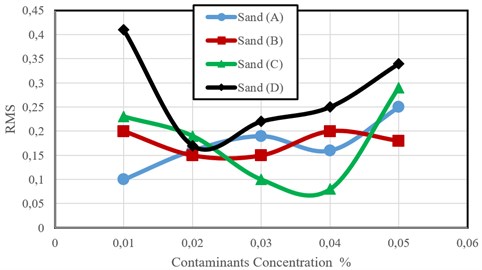

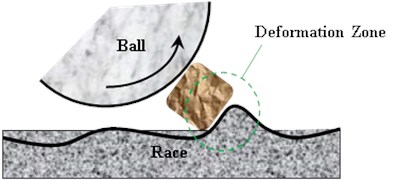

The experimental results were carried out in two groups. The first group is depending on adding different particles size of the silica with different concentrations. The added silica has particles size of (0-150 μm) “A”, (150-300 μm) “B”, (300-600 μm) “C”, and (600-1400 μm) “D”, as shown in Fig. 1. Fig. 3 illustrates the variation of RMS amplitude of the acceleration for ball bearing with concentration of added silica. It shows that when the additive concentration of particles is increased, the RMS amplitude increases. The variation of RMS values may be due to the interaction of silica particles on the contact area between the balls and the races of the bearing, as shown in Fig. 4.

Fig. 3RMS acceleration amplitude versus contaminants concentration for grope A

Fig. 4A sketch of contaminants deformation in contact area of bearing

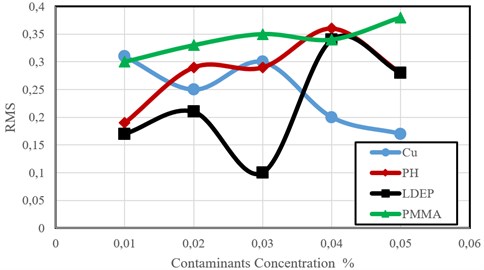

The lubricant specimens after the test were analyzed. Images of cutting particles found in the lubricant samples from silica “A” were shown in Fig. 5. It was observed that the silica “A”, particles size of (0-150 μm), has greater effect on the increase of the wear rate. It can be concluded that the RMS give high results with increase of the concentration of silica through disturbing and breaking the grease film inside the bearing. Moreover, the wear rate increased with the decrease of silica particles size. The second group is tested with adding copper (Cu micro particles), poly methyl methacrylate (PMMA), low-density polyethylene (LDPE), and polyamide (PA) to solid lubricant. The variation of RMS amplitude of the acceleration for ball bearing with concentration of added silica are shown in Fig. 6. It is observed that the increase of the RMS amplitude due to increase of the concentration of the polymeric additives. Also, it is noticed that poly methyl methacrylate (PMMA) gives higher values of RMS acceleration amplitude. Furthermore, the RMS amplitude values decreased when the concentration of the copper particles increased.

Fig. 5The morphology of lubricant specimen of silica A

Fig. 6RMS acceleration amplitude versus contaminants concentration for grope B

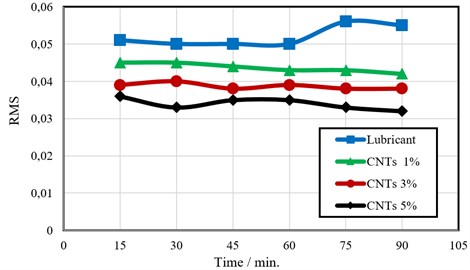

3.2. Analysis of carbon nanotubes CNTs adding

Fig. 6 illustrates the variation of RMS amplitude of the acceleration for ball bearing with time. In the experiment, the RMS amplitudes were measured every second. The RMS amplitude averaged from every 15 min. original data were displayed in Fig. 7. It is important to notice that the RMS amplitudes of lubricant with carbon nanotubes CNTs are all smaller than that of pure lubricating grease. It can be concluded that the vibration performance was improved due to increase of concentration of carbon nanotubes CNTs.

Fig. 7Experimental variation of the acceleration RMS with time

4. Conclusions

In the present work, the effect of solid contaminants in grease on vibration response of ball bearing was studied. For bearing with contaminant free grease, all the frequencies are at minimum level. As the contaminants particles size and concentration are increased, the corresponding acceleration values also increase up to certain limit. Furthermore, the vibration amplitudes decrease due to increase of the copper concentration.

With smaller particle size and varying concentration level of silica, the wear rate gives the highest results. This may be attributed to the fact that particles may come in direct contact with rotating elements, break the grease film separating the contacting elements of the bearing.

Due to carbon nanotubes CNTs, which was 0.5 wt. %, introduced in a lithium grease, the vibration amplitudes of bearings is reduced by 32 %.

References

-

Roylance B. J., Hunt T. M. Wear Debris Analysis. Coxmoor Publishing Company, Oxford, UK, 1999.

-

Braron T. Engineering Condition Mointoring. Addison Wesley Longman, 1996.

-

Miettinen Juha, Andersson Peter Acoustic emission of rolling bearings lubricated with contaminated grease. Tribology International, Vol. 33, 2000, p. 777-787.

-

Serrato Ricardo, Maru Marcia, Padovese Linilson Effect of lubricant oil viscosity and contamination on the Mechanical signature of roller bearing. 12th International Conference on Sound and Vibration, Vol. 87, 2005, p. 514-567.

-

Serrato R., Maru M. M., Padovese L. R. Effect of lubricant viscosity grade on mechanical vibration of roller bearings. Tribology International, Vol. 40, 2007, p. 1270-1275.

-

Maru M. M., Castillo R. S., Padovese L. R. Study of solid contamination in ball Bearings through vibration and wear analyses. Tribology International, Vol. 40, 2006, p. 433-44.

-

Maru Marcia Marie, Castillo Ricardo Serrato, Padovese Linilson Rodrigues Effect of the presence of solid contamination and the resulting wear on the mechanical signature of ball bearings. 18th International Congress of Mechanical Engineering, Ouro Preto, MG, 2005.

-

Mahajan Onkar L., Utpat Abhay A. Study of effect of solid contaminants in the lubricant on ball bearings vibration. International Journal of Instrumentation, Control and Automation, Vol. 1, 2012.

-

More Yogesharao Y., Deshmukh A. P. Study of effect of solid contaminants in grease on performance of ball bearing by vibrational analysis. International Journal of Innovations in Engineering Research and Technology, Vol. 2, Issue 5, 2015.

-

Godase Sachin P., Nehe S. S., Anatharama B. Analysis of effect of solid contaminants in lubrication on vibration response of ball bearing. International Engineering Research Journal, Vol. 1, Issue 7, 2015, p. 545-549.

-

Radice S., Mischler S. Effect of electrochemical and mechanical parameters on the lubrication behaviour of Al2O3 nanoparticles in aqueous suspensions. Wear, Vol. 261, 2006, p. 1032-1041.

-

Shi G., Zhang M. Q., Rong M. Z., Bernd W., Klaus F. Sliding wear behavior of epoxy containing nano Al2O3 particles with different pretreatments. Wear, Vol. 256, 2004, p. 1072-1081.

-

Li X. H., Cao Z., Zhang Z. J., Dang H. X. Surface-modification in situ of nano SiO2 and its structure and tribological properties. Applied Surface Science, Vol. 252, 2006, p. 7856-7861.

-

Peng D. X., Kang Y., Hwang R. M., Shyr S. S., Chang Y. P. Tribological properties of diamond and SiO2 nanoparticles added in paraffin. Tribology International, Vol. 42, 2009, p. 911-917.

-

Ma S. Y., Zheng S. H., Ding H. Y., Li W. Anti-wear and reduce-friction ability of ZrO2/SiO2 self-lubricating composites. Advanced Materials Research, Vols. 79-82, 2009, p. 1863-1866.

-

Li W., Zheng S. H., Ma S. Y., Ding H. Y., Jiao D., Cao B. Q. Study of surface modification of ZrO2/SiO2 nano composites with aluminum zirconium coupling agent. Asian Journal of Chemistry, Vol. 23, 2011, p. 705-708.

-

Gu C. X., Li Q. Z., Gu Z. M., Zhu G. Y. Study on application of CeO2 and CaCO3 nanoparticles in lubricating oils. Journal of Rare Earth, Vol. 26, 2008, p. 163-167.

-

Mangam V., Bhattacharya S., Das K., Das S. Friction and wear behavior of Cu-CeO2 nano composite coatings synthesized by pulsed electrode position. Surface and Coatings Technology, Vol. 205, 2010, p. 801-805.

-

Jiao Da, et al. The tribology properties of alumina/silica composite nanoparticles as lubricant additives. Applied Surface Science, Vol. 257, 2011, p. 5720-5725.

-

Prakash E., Kumar Siva, Kumar Muthu Experimental studies on vibration characteristics on ball bearing operated with copper oxide nano particle mixed lubricant. International Journal of Engineering and Technology, Vol. 5, 2013, p. 4127-4130.