Informatics

Editor's pick

Research Article

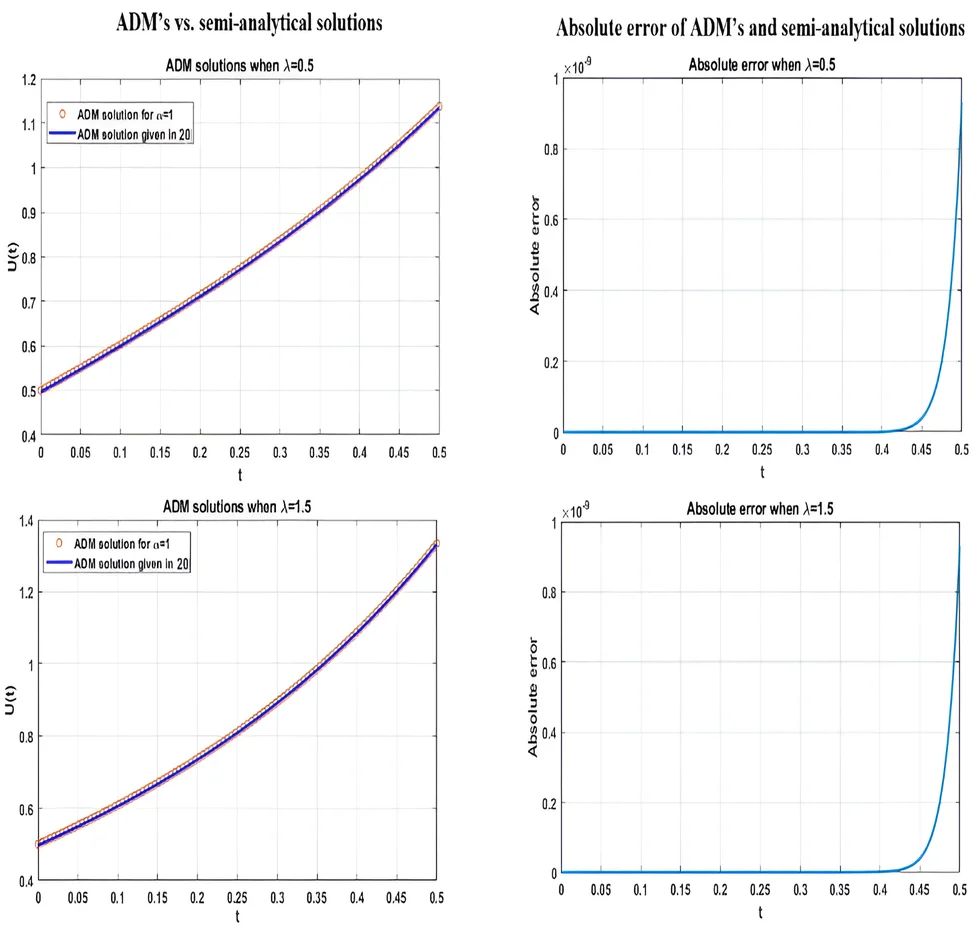

A simple harmonic quantum oscillator: fractionalization and solution

By Iqbal M. Batiha, Iqbal H. Jebril, Abeer A. Al-Nana, Shameseddin Alshorm

A quantum mechanical system that mimics the behavior of a classical harmonic oscillator in the quantum domain is called a simple harmonic quantum oscillator. The time-independent Schrödinger equation describes the quantum harmonic oscillator, and its eigenstates are quantized energy values that correspond to various energy levels. In this work, we first fractionalize the time-independent Schrödinger equation, and then we solve the generated problem with the use of the Adomian decomposition approach. It has been shown that fractional quantum harmonic oscillators can be handled effectively using the proposed approach, and their behavior can then be better understood. The effectiveness of the method is validated by a number of numerical comparisons.

March 2, 2024

Informatics

Most cited

Research Article

Optimization of palm methyl ester and its effect on fatty acid compositions and cetane number

By Sharath Satya, Aditya Kolakoti, Naga Raju B., Shyam Sundar R., Ranga Rao

March 31, 2019

Informatics

Most cited

Research Article

Optimization and modelling of mahua oil biodiesel using RSM and genetic algorithm techniques

By Aditya Kolakoti, Panchanand Jha, Prakasa Rao Mosa, Manohar Mahapatro, Tulasi Ganesh Kotaru

June 2, 2020

Informatics

Most cited

Research Article

Mathematical modeling of forced oscillations of semidefinite vibro-impact system sliding along rough horizontal surface

By Vitaliy Korendiy, Volodymyr Gursky, Oleksandr Kachur, Volodymyr Gurey, Oleksandr Havrylchenko, Oleh Kotsiumbas

December 2, 2021

Informatics

Most cited

Research Article

Performance of PID-Fuzzy control for cab isolation mounts of soil compactors

By Vanliem Nguyen, Renqiang Jiao, Vanquynh Le, Anhtan Hoang

December 31, 2019

Informatics

Robotic Systems and Applications

Research Article

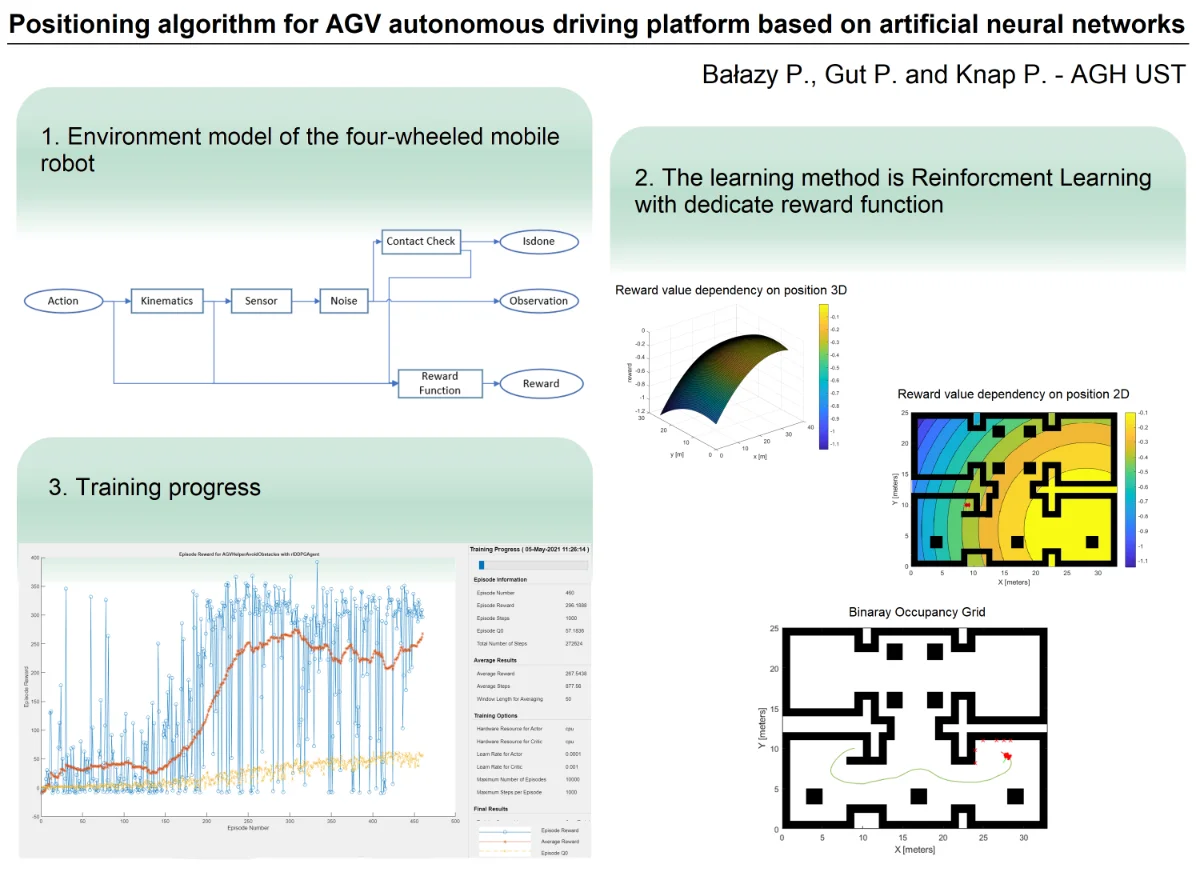

Positioning algorithm for AGV autonomous driving platform based on artificial neural networks

This paper presents an artificial intelligence algorithm responsible for the autonomy of a platform. The proposed algorithm allows the platform to move from an initial position to a set one without human intervention and with understanding and response to the dynamic environment. The implementation of such a task is possible by using a combination of a camera identifying the environment with a laser LIDAR sensor and a vision system. The signals from the sensors are analysed through convolutional neural networks. Based on AI inference, the platform makes decisions, including determining the optimal path for itself. A transfer learning method will be used to teach the neural network. This article presents the results of learning the applied neural algorithm.

August 11, 2021

Biomechanics

Research Article

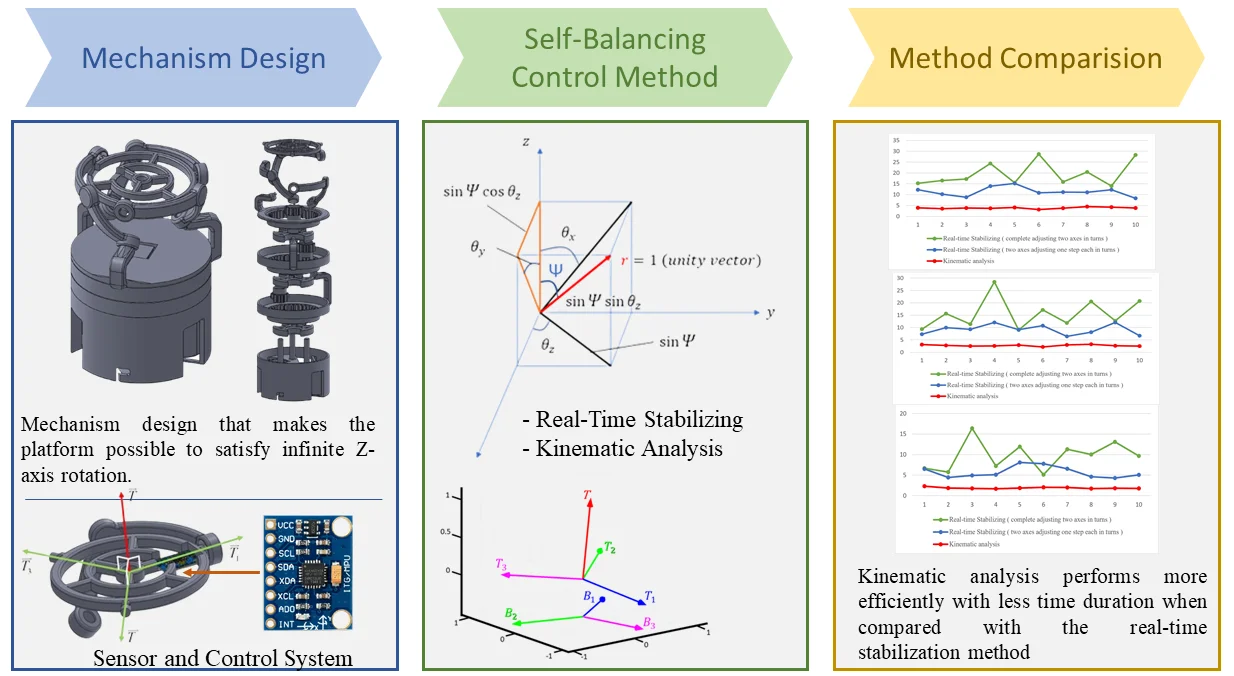

Designing and controlling a self-balancing platform mechanism based on 3-RCC spherical parallel manipulator

Motion control platforms have various applications in the manufacturing and automation industries. Different literature provides multiple issues related to the kinematics and dynamics of self-guided robots for transportation regarding platform balancing. Self-balancing platforms are utilized in many deliveries, stabilization, and transportation systems, and they are especially well suited for outdoor activities when the ground surface is not flat or structured. This paper describes developing a control technique for a self-balancing platform using the 3-RCC spherical parallel manipulator. This mechanism was designed to support an AGV (Automated Guided Vehicle) for transporting and lifting heavy weights for industrial applications. The AGV carries a robotic arm on top for different tasks. When the AGV encounters a steep slope or a rough surface, the AGV tilts, and the robotic arm’s performance is significantly affected. So, this study gives a solution to avoid these circumstances with a novel approach for the platform’s self-balancing mechanism consisting of a 3-RCC spherical parallel manipulator. Real-time stabilization and kinematics analysis methods are used to achieve the self-balancing system of the platform. When both methods are observed through different tilting angles for automation stability, Kinematic analysis performs more efficiently with less time duration when compared with the real-time stabilization method.

March 2, 2023

Biomechanics

Research Article

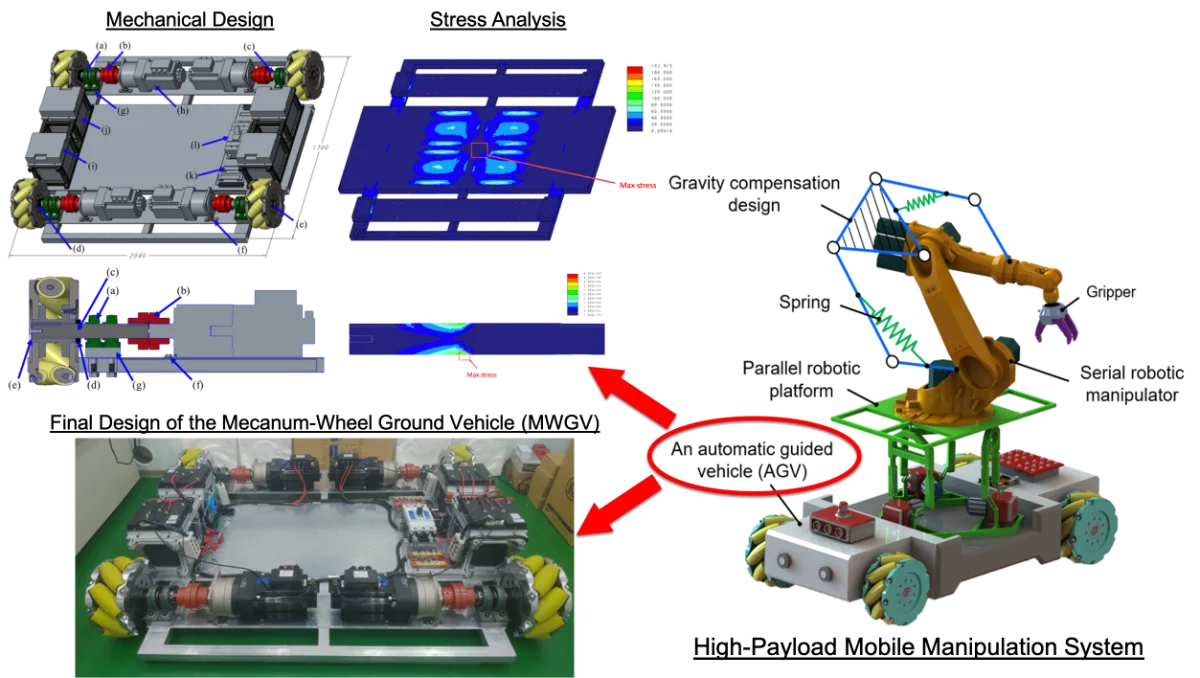

Design of a high-payload Mecanum-wheel ground vehicle (MWGV)

With the rapid developments of Industry 4.0 and Smart Manufacturing, customized manufacturing has been becoming greatly needed. Meanwhile, the challenge of production automation has become more bigger, especially for the automation of moving, picking, placing and manipulating objects. Many researchers have begun to work on Autonomous Ground Vehicles (AGVs). Most AGVs were utilized to carry middle or small objects, as the high-payload AGVs were rarely developed. This paper focused on the design of a High-Payload Mecanum-Wheel Ground Vehicle (MWGV), which was 1.7 m wide and 2.04 m long. The weight of the vehicle was 740 kg and it was able to carry the payload as its own weight (i.e. around 7,300 N). The safety factor of the structural strength was greater than 1.66 and the safety factor of the axial design was at least 6.24. The vehicle was designed to carry 150-kg weight with a reach of 1.375 m without falling. The design of Mecanum wheels provided great flexibility on movement with small rotational radius. Mathematical descriptions about how Mecanum wheels were controlled was also introduced in this paper. Furthermore, the mechatronics and software integrations were demonstrated. The final experimental results showed the developed MWGV was able to perform the desired movement properly.

June 30, 2021

Biomechanics

Research Article

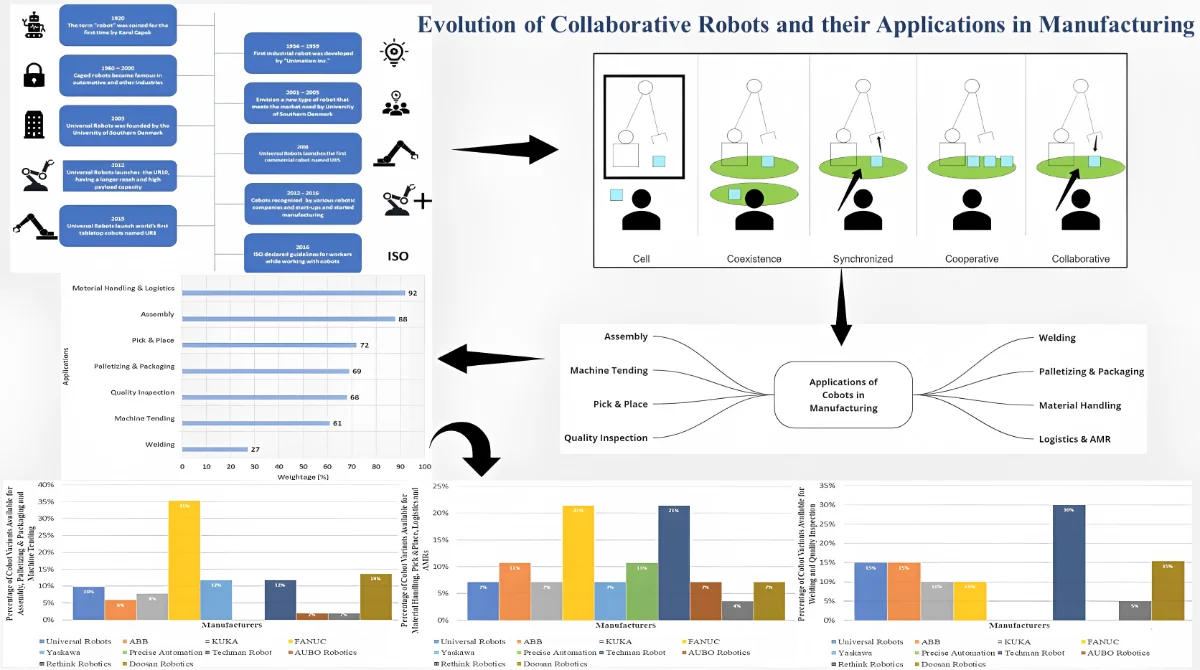

Applications of collaborative robots in agile manufacturing: a review

Collaborative robots are machines that work hand in hand with humans; or as the name suggests, collaborate with them in a specific workspace. These robots are not enclosed in confined safety zones like traditional robots, as they interact very closely with humans. Though this is the case, appropriate measures are captivated while designing these robots considering human safety. These robots are well-versed in adapting to changes and frequent upgrades. They are flexible enough to carry out complex tasks. Due to these abilities, they become a significant asset in the manufacturing field. It’s been many years now since cobots are introduced in the industry sector. So, this is the right time to review various applications of cobots in manufacturing. First, the paper starts with a brief introduction followed by an extensive literature review which was structured after reviewing 76 research papers and articles. It ends with some essential conclusions. This paper discusses the diverse applications of cobots used in the manufacturing sector and their advantages. Further, it highlights the future of cobots and how they will be a boon for a technology-driven world.

June 26, 2023

Biomechanics

Robotic Systems and Applications

Fundamental and applied aspects in robotics

APC

Free of charge

Best of Theme

Most cited

Research article

October 19, 2020

An improved mesh stiffness calculation model of spur gear pair under mixed EHL friction with spalling effect

By Siyu Wang, Rupeng Zhu

Most cited

Research article

June 25, 2019

Dynamic optimization mathematical model of the military subordinating interaction of two states

By Valeriy K. Zakharov

Most cited

Research article

March 31, 2020

Study on microstructure mechanism of sandstone based on complex network theory

By Liu Guannan, Ye Dayu, Liang Xin, Zhu Xiaoqian, Gao Feng

Most cited

Research article

March 31, 2020

Mathematical modelling of rolling element bearings fault for the diagnosis in the gearbox-induction machine

By Azeddine Ratni, Djamel Benazouz

You might also like

Most downloaded

Research Article

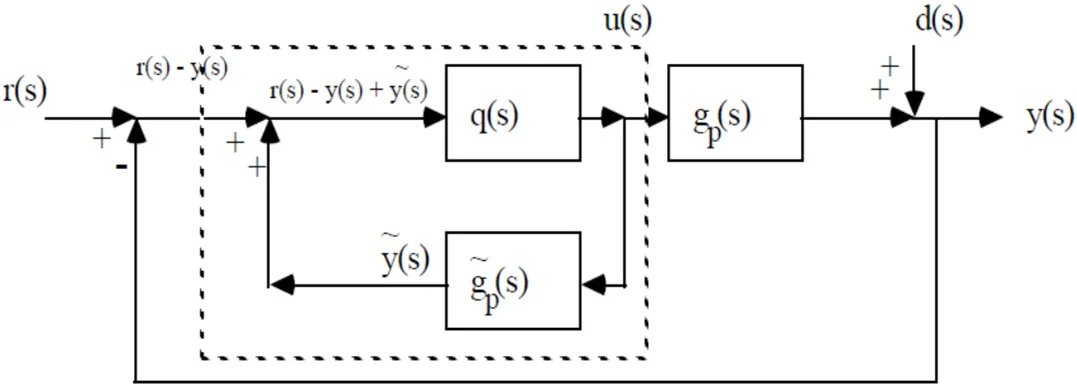

Mathematical modeling of first order process with dead time using various tuning methods for industrial applications

By Sathish Kumar Shanmugam, Yuvaraj Duraisamy, Meenakumari Ramachandran, Senthilkumar Arumugam

The proposed research involves Mathematical modeling for first order process with dead time using various tuning methods for industrial applications. Different tuning methods are proposed. Proposed method selection depends on plant operating conditions and also depending upon the process dynamics. The PID controller is most widely used for industrial process control. Modeling were developed for modified internal control model [4-6] in this proposed research. The proposed work is the modeling and simulation of three different first order processes with dead time. The standard controller tuning method is used to obtain the steady state response of first order with dead time.

March 31, 2019

Informatics

Most downloaded

Research Article

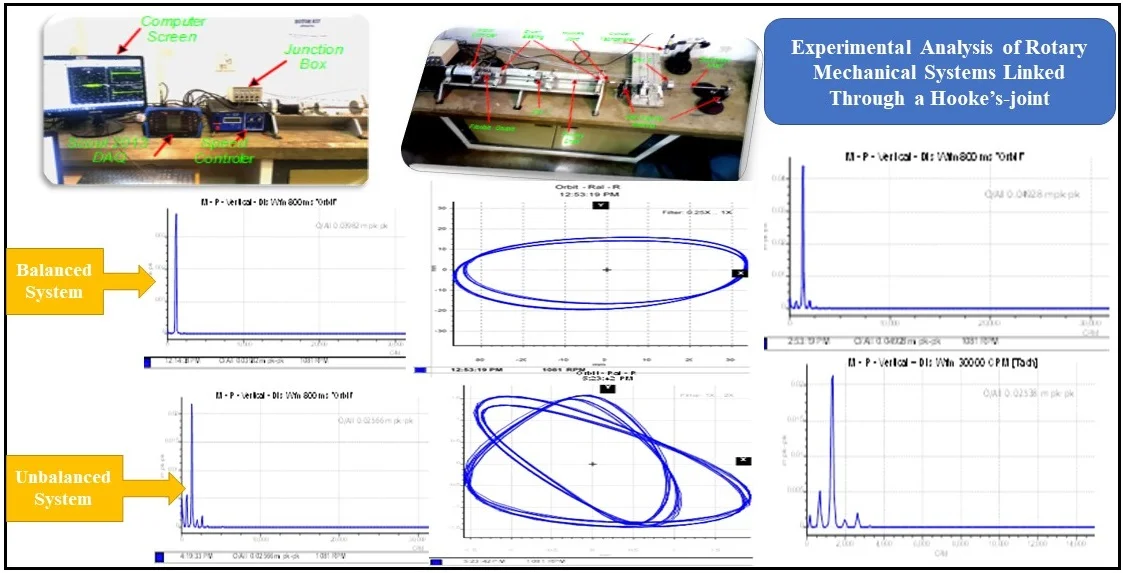

Experimental setup for unbalance fault detection and vibration analysis in a cardan shaft (Part B)

By Bernard Xavier Tchomeni, Alfayo Anyika Alugongo, Leonard Masu

This paper experiments a vibration measurement on a twin-rotor connected by a Hooke’s joints. An experimental set-up for vibration analysis and unbalance fault detection in rotating machinery has been conducted to reveal the unbalance effect in signal transmission of the interconnected shaft through Hooke’s joint. Vibrations signals were measured and analysed using the Fast Fourier Transform (FFT), orbit patterns and time displacement of each rotor centre, to extract the signature of the unbalance fault. The results indicate the accuracy of the discussed approach for the twin-rotor unbalances diagnosis in an interconnected shafts system through a Hooke’s joint.

September 30, 2019

Informatics

A study on determining the maintenance task interval of the flight trainer aircraft system

To formulate a plan of maintenance, the key aspect is to determine the maintenance intervals, as the maintenance types and maintenance intervals of each system are provided in the maintenance plan, and the types of each system are usually fixed. In this paper, the using data of aircraft components was employed to determine the maintenance interval. The least-squares method was adopted to estimate the Weibull distribution parameter. Then, the maintenance task interval model was set up. At last, the method was verified by using the reliability data of landing gear in in CESSNA172R.

Computational fluid dynamics (CFD) modelling of hybrid photovoltaic thermal system

In this paper an attempt has been made to simulate and evaluate the distribution of temperature and heat flux for the hybrid photovoltaic thermal system with CFD (computational fluid dynamics) module in ANSYS 19.1 software. The simulation was carried to determine the temperature and heat flux across the different layers of HPVT (hybrid photovoltaic thermal) system. The temperature and heat flux were found to gradually decrease from the top glass layer to the bottom tedlar layer. The temperature varied from 36.4 °C (ambient) to 26.8 °C across the layers from top glass layer to bottom tedlar layer. The heat flux of (561.2 W/m2) at the glass layer due to solar insolation was also found to gradually decrease with the increasing thickness. The reduction in temperature and heat flux with increasing thickness is attributed to fluid flowing beneath the system. The water flowing beneath the tedlar layer takes the excess heat out of the photovoltaic layer, thereby increasing the efficiency of the hybrid photovoltaic thermal system.